Modern construction and industrial roofing require materials that combine high performance, long service life, and resistance to demanding environments. As industries move toward lightweight, durable, and sustainable alternatives, pultruded FRP structural profiles have become one of the most reliable solutions. In Vietnam, THE FRONT, with its STRONX product line, is recognized as a leading pultruded FRP structural profiles manufacturer in Vietnam, delivering innovative roofing and construction solutions.

What Are Pultruded FRP Structural Profiles?

Pultrusion is a continuous manufacturing process in which fiberglass reinforcements are saturated with resin and pulled through a heated die, creating constant cross-sectional profiles. The result is FRP pultruded profiles that are lightweight yet extremely strong, resistant to corrosion, and adaptable for multiple applications.

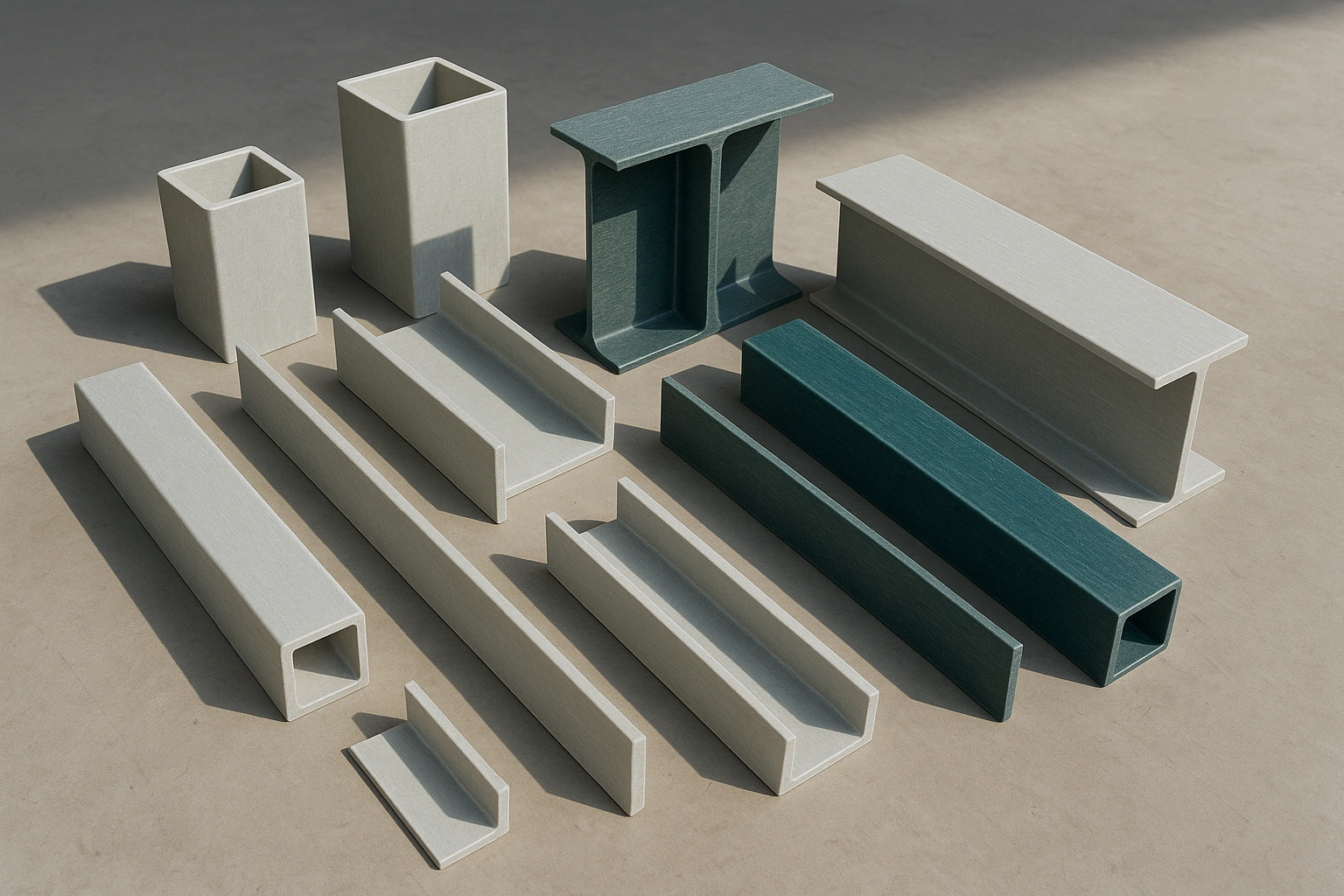

These FRP structural profiles can be produced in different shapes and sizes, including I-beams, channels, angles, tubes, and FRP purlins. Their uniformity, dimensional accuracy, and mechanical properties make them superior to conventional steel or aluminum in many construction and roofing scenarios.

Advantages of Pultruded FRP Structural Profiles

THE FRONT has engineered its STRONX pultruded FRP profiles to meet the toughest industrial requirements. Key advantages include:

- Lightweight strength: Up to 70% lighter than steel, reducing transportation and installation costs.

- Corrosion resistance: Withstands exposure to moisture, chemicals, and saline environments.

- Electrical insulation: Non-conductive, ensuring safety in environments with high-voltage equipment.

- Dimensional stability: Maintains performance in fluctuating temperatures and humid conditions.

- Low maintenance: Eliminates frequent painting, galvanizing, or replacement.

These properties make FRP profiles for construction especially suitable for industrial roofing, chemical plants, coastal infrastructure, and renewable energy projects.

FRP Purlins for Industrial Roofing Solutions

One of the most important applications of pultruded FRP profiles is in roofing systems. FRP purlins serve as the load-bearing members that support roof sheets and panels. Unlike steel, FRP purlins are not affected by corrosion, ensuring long-term durability even in humid or chemical-intensive environments.

In large-scale warehouses, food processing plants, or coastal factories, FRP purlins help reduce structural load while improving the lifespan of roofing systems. When integrated with translucent or anti-corrosion roofing sheets, FRP purlins contribute to sustainable, low-maintenance industrial facilities.

Applications of Pultruded FRP Structural Profiles

The versatility of pultruded FRP structural profiles extends beyond roofing. Their unique mechanical and chemical resistance properties allow wide-ranging use across industries:

- Industrial roofing and purlins: Long-span support structures resistant to moisture and chemicals.

- Construction frameworks: I-beams, channels, and angles for structural supports.

- Cooling towers: Lightweight profiles resistant to constant water exposure.

- Chemical processing plants: Structural solutions resistant to corrosive fumes and liquid spills.

- Marine and coastal infrastructure: Bridges, walkways, and platforms exposed to saltwater.

- Renewable energy projects: Support structures for solar panels and wind turbines.

These applications of pultruded FRP structural profiles demonstrate their adaptability across industries requiring corrosion resistance, strength, and lightweight design.

FRP Pultruded Profiles: Shapes and Dimensions

THE FRONT’s STRONX pultruded FRP profiles are manufactured in a wide variety of shapes and dimensions to meet custom project requirements. Standard options include:

- I-Beams: High strength for vertical and horizontal load applications.

- Channels and Angles: Versatile framing members for construction.

- Rectangular and Square Tubes: Used in frameworks, railings, and support structures.

- FRP Purlins: Optimized for roofing solutions with multiple span capabilities.

Custom sizes and colors are also available, allowing architectural flexibility while ensuring consistent performance. Dimensional precision ensures easy integration with existing steel or concrete structures.

Manufacturing Excellence in Vietnam

Vietnam has become a hub for advanced composite production, and THE FRONT is at the forefront of this progress. With the STRONX brand, the company has invested in modern pultrusion lines, strict quality control, and advanced resin systems to produce profiles that meet international standards.

As a trusted FRP structural profiles manufacturer, THE FRONT provides solutions tailored to both domestic and global markets. By leveraging local expertise and global technology, the company ensures that its FRP products are competitive in performance, cost, and sustainability.

Why Choose THE FRONT and STRONX for Pultruded FRP Structural Profiles?

When selecting a pultruded FRP structural profiles manufacturer in Vietnam, several factors determine long-term project success: material quality, design flexibility, and proven field performance. THE FRONT, through its STRONX product line, provides all of these:

- Comprehensive product range: From purlins to beams, channels, and custom profiles.

- Corrosion-free performance: Long service life in harsh industrial and marine environments.

- Lightweight solutions: Reduced structural load and easier installation.

- Global quality assurance: Compliance with international engineering standards.

- Sustainable production: Energy-efficient processes and recyclable composites.

By choosing THE FRONT and STRONX, clients secure a reliable partner in building industrial roofing and structural systems designed for durability, efficiency, and safety.

As industries demand stronger, lighter, and more corrosion-resistant materials, pultruded FRP structural profiles provide the perfect balance between performance and sustainability. From FRP purlins in industrial roofing to custom FRP profiles for construction, their applications are reshaping modern infrastructure.With THE FRONT as a leading pultruded FRP structural profiles manufacturer in Vietnam, supported by the STRONX brand, businesses gain access to world-class composite solutions tailored for industrial, marine, and construction environments. By investing in pultruded FRP profiles, project owners ensure long-term savings, reduced maintenance, and superior performance in even the most challenging conditions.