In large-scale infrastructure, industrial, and marine projects, the selection of advanced materials such as FRP (Fiber Reinforced Plastic) is essential. Yet material choice alone does not determine success. What matters is how effectively those materials are designed, produced, and delivered in alignment with the project’s technical and operational demands.

This is where partnerships with a capable FRP manufacturer make the difference. Not just a source of panels or gratings, a true OEM partner provides tailored FRP solutions across a broad product spectrum, ensuring every stage of the project design, execution, and operation benefits from technical precision and long-term reliability.

The Strategic Value of OEM FRP Partnerships

An OEM FRP manufacturer is more than a supplier. They function as a strategic partner designing, engineering, and fabricating solutions that align directly with project needs. This approach ensures that FRP components are not generic, but optimized for specific technical, operational, and safety requirements.

For instance, a port development may need gratings with higher load-bearing capacity, while a power plant may require FRP roofing with fire-retardant properties. A capable composite manufacturer integrates these demands into the design and production process, ensuring projects are delivered faster, with reduced risks and higher lifecycle value.

A Broad Spectrum of OEM FRP Solutions

The defining strength of a modern composite manufacturer lies in product diversity and the ability to deliver OEM solutions across industries. Instead of specializing in a single product category, a capable FRP partner provides a wide portfolio, including but not limited to:

- Roofing and Cladding Systems – for industrial, commercial, and public buildings.

- FRP Panels and Translucent Sheets – engineered for daylighting, insulation, and fire resistance.

- Grating Composite FRP Systems – anti-slip, lightweight solutions for walkways and platforms.

- Structural Profiles and Channels – pultruded FRP components designed for strength and modularity.

- Tanks and Vessels – corrosion-resistant solutions for chemical and water storage.

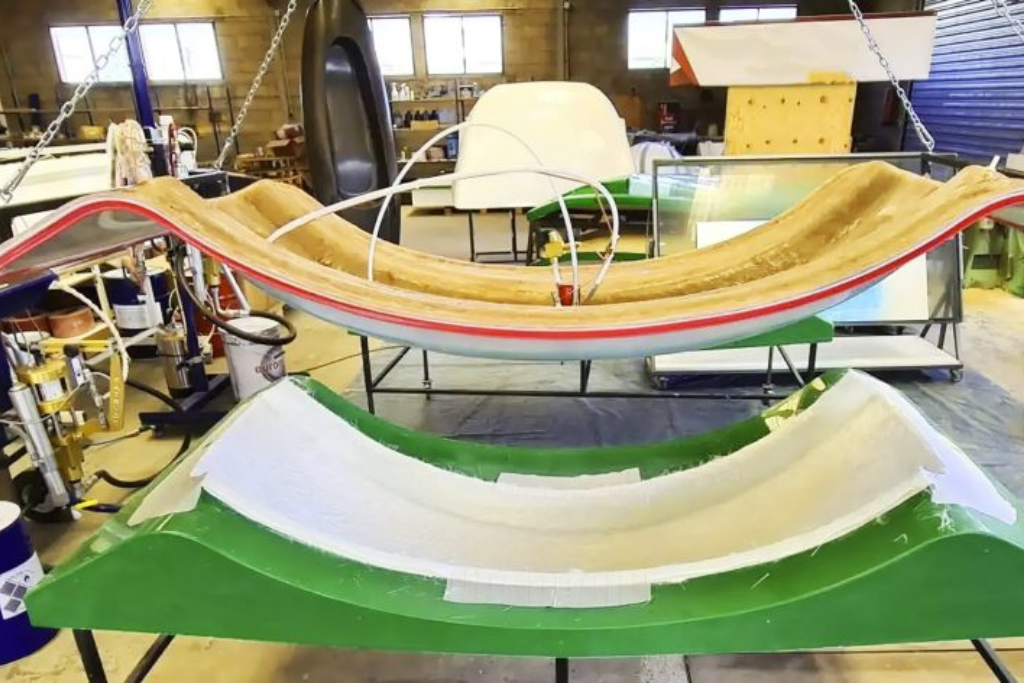

- Custom OEM FRP Products – components for machinery, transportation, or specialized equipment.

This range illustrates how OEM FRP products are not limited to a single sector. Instead, they represent a toolkit of customizable solutions, adaptable to industries as diverse as energy, transport, marine, and architecture.

Key Benefits of Partnering with a Trusted FRP Manufacturer

Flexibility and Customization

OEM partnerships allow project teams to define specifications – size, resin system, reinforcement type, or performance criteria—while the manufacturer delivers precisely engineered products.

Assured Quality and Long-Term Reliability

With rigorous production controls and material testing, OEM manufacturers ensure consistency across every product line. Whether it is FRP roofing, gratings, or custom components, quality assurance translates into predictable long-term performance.

Technical Expertise Integrated into Projects

A strong FRP partner contributes more than finished goods. Engineering support covers resin optimization, fire and UV resistance strategies, structural load analysis, and installation guidance. This expertise enhances safety margins while reducing on-site complications.

Scalable Global Supply

Infrastructure and industrial projects often require large volumes delivered within strict timelines. A capable OEM FRP manufacturer balances scale with quality, ensuring supply stability for projects worldwide.

Lifecycle Value

The inherent advantages of FRP low maintenance, corrosion resistance, durability become even more valuable when combined with strategic manufacturing support. Projects benefit from solutions optimized for operational efficiency over decades.

Industry Applications of OEM FRP Partnerships

Strategic OEM partnerships add value across industries where material performance is critical:

- Industrial and Chemical Facilities: corrosion-resistant panels, tanks, and roofing systems engineered to withstand aggressive environments.

- Marine and Offshore Structures: lightweight FRP gratings, decks, and cladding that maintain performance against saltwater and UV exposure.

- Infrastructure and Civil Engineering: pedestrian bridges, structural supports, and public walkways designed with durable FRP composites.

- Architectural Projects: translucent sheets and roofing systems that combine daylighting, fire resistance, and modern design.

- OEM Equipment Manufacturing: customized FRP parts for transportation, machinery, and specialized industrial systems.

This versatility demonstrates that FRP manufacturing partnerships are not limited to construction they extend across global sectors that demand lightweight, high-strength, and corrosion-resistant materials.

The Front – A Comprehensive OEM FRP Partner

As a leading composite manufacturer, The Front exemplifies the qualities of a long-term OEM partner. The company’s strength lies not in a single product, but in the breadth of solutions it provides: from FRP roofing and panels to gratings, tanks, structural profiles, and fully customized OEM FRP products.

Distinct Advantages of Partnering with The Front

- Diverse OEM Capabilities – A wide manufacturing portfolio covers roofing, panels, gratings, tanks, structural parts, and custom FRP accessories.

- R&D-Driven Innovation – Continuous research enhances resin systems for UV stability, fire performance, and durability.

- Scalable Global Production – Advanced lines support international projects with reliable, on-time supply.

- Full Lifecycle Support – From specification to after-sales services, The Front offers complete technical consultation for FRP applications.

In today’s competitive and demanding construction and industrial landscape, success depends on more than material choice. It is defined by partnerships specifically, partnerships with OEM FRP manufacturers capable of delivering technical depth, product diversity, and long-term commitment.

By choosing The Front, stakeholders gain not just a supplier, but a strategic ally. With expertise spanning FRP roofing, gratings, panels, tanks, structural profiles, and custom OEM solutions, The Front provides the diversity, flexibility, and reliability required to ensure projects succeed from inception through decades of operation.