In any electrical or communication system, proper cable management is essential for both safety and system performance. One of the most effective ways to manage and protect cables is by using a cable trough. Whether installed inside a building or across outdoor spaces, cable troughs offer an organized, durable solution that safeguards wiring infrastructure — a growing need in industrial and infrastructure projects throughout Vietnam.

However, not all cable troughs are the same — and choosing between indoor and outdoor cable troughs involves understanding specific requirements, materials, and conditions. In this guide, we’ll break down the key differences, applications, and what you need to know to select the right cable trough for your project.

What Is a Cable Trough?

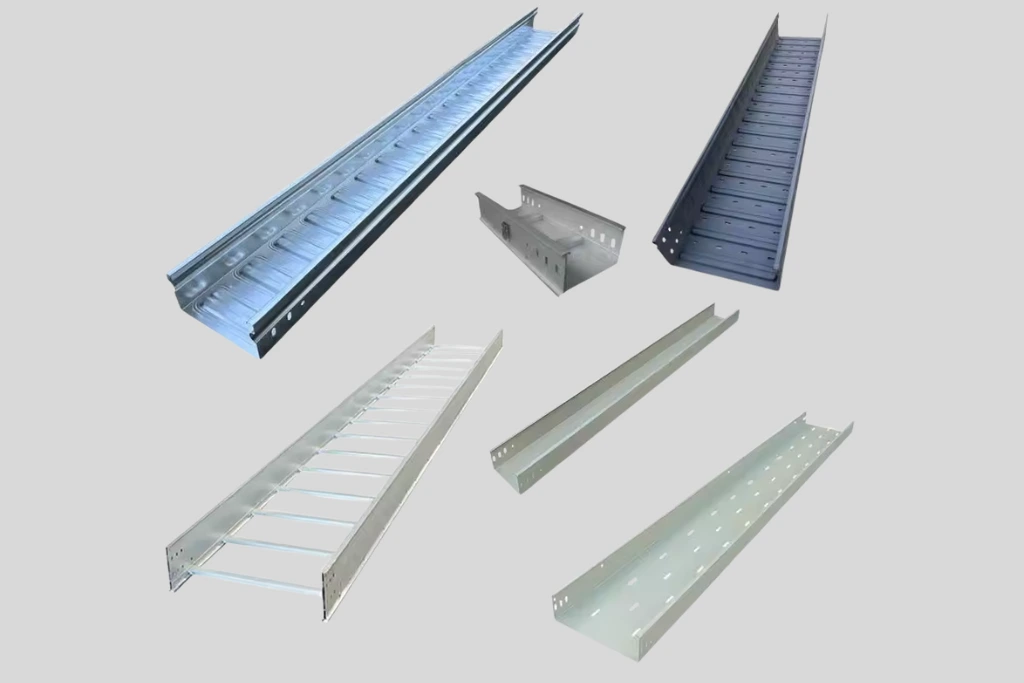

A cable trough is a protective enclosure, channel, or conduit system designed to route and shield groups of electrical, data, or telecommunication cables.

Cable troughs serve several important purposes:

- Protect cables from mechanical damage

- Organize complex wiring systems

- Shield against moisture, chemicals, and UV rays

- Support cable ventilation and prevent overheating

- Simplify maintenance and upgrades

They are commonly installed along walls, ceilings, floors, underground, or overhead in a wide range of industries — from data centers and manufacturing plants to railways and renewable energy facilities.

Key Differences Between Indoor and Outdoor Cable Troughs

| Feature | Indoor Cable Troughs | Outdoor Cable Troughs |

|---|---|---|

| Material Options | PVC, FRP, aluminum | FRP, stainless steel, galvanized steel, concrete |

| Environmental Exposure | Controlled environments (moderate humidity, dust) | Severe conditions (UV, rain, temperature extremes, chemicals) |

| Strength Requirements | Light to moderate loads | Heavy-duty load bearing for vehicular traffic or heavy equipment |

| Installation Requirements | Lightweight, simple fixings | Reinforced supports, drainage considerations |

| Maintenance Needs | Minimal | Depends on material, frequent inspections for damage or exposure |

Indoor and outdoor cable troughs must be selected and designed according to their working environments to guarantee safety, longevity, and functionality.

Indoor Cable Troughs: Features and Best Practices

Indoor cable troughs focus on organizing cables within controlled environments such as offices, hospitals, factories, and educational buildings.

Key Characteristics:

- Lightweight for easy installation on ceilings, walls, or under raised floors.

- Made of corrosion-resistant, fire-rated materials like PVC or FRP.

- Designed for clean aesthetics to blend into the environment.

- Provides easy access for maintenance or future upgrades.

Ideal Applications:

- Data centers (for managing fiber optics and Ethernet cables)

- Hospitals (for patient monitoring systems and emergency backup wiring)

- Schools and universities (for IT networks, audio-visual systems)

- Office buildings (for power, HVAC, and communications)

Installation Tips:

- Use modular designs for easier expansion.

- Allow sufficient ventilation for heat-sensitive cables.

- Label cable paths clearly to simplify future maintenance.

Outdoor Cable Troughs: Features and Best Practices

Outdoor cable troughs must stand up to much harsher environments where they face natural and industrial threats daily.

Key Characteristics:

- Designed to be waterproof, UV-resistant, and corrosion-proof.

- Built with heavy-duty load-bearing capabilities for vehicular access.

- Often designed with locking covers for security and additional protection.

- May include built-in drainage channels to prevent water buildup.

Ideal Applications:

- Railways (protecting control and signal cables along tracks)

- Solar farms (routing photovoltaic system wiring)

- Oil and gas plants (cabling for pumps and sensors)

- Airport tarmacs and highways (power and communications routing)

Installation Tips:

- Ensure proper drainage to prevent flooding inside the trough.

- Use expansion joints if long runs are exposed to significant temperature changes.

- Choose troughs with locking lids to prevent unauthorized access or vandalism.

Factors to Consider When Selecting a Cable Trough

Before choosing a cable trough, whether for indoor or outdoor use, think about these important factors:

1. Cable Type and Volume

Estimate the number and size of cables to prevent overcrowding, which can cause overheating and mechanical stress.

2. Environmental Conditions

Assess whether the environment exposes the system to moisture, UV light, chemicals, salt air, or mechanical impacts.

3. Load Requirements

Indoor systems may only need lightweight support, but outdoor systems often require high-strength materials to handle vehicle loads or heavy foot traffic.

4. Fire Safety and Regulations

Select materials that comply with fire ratings and local codes — crucial in hospitals, schools, and public spaces.

5. Future Expandability

Choose modular or oversized systems if you anticipate future cable additions.

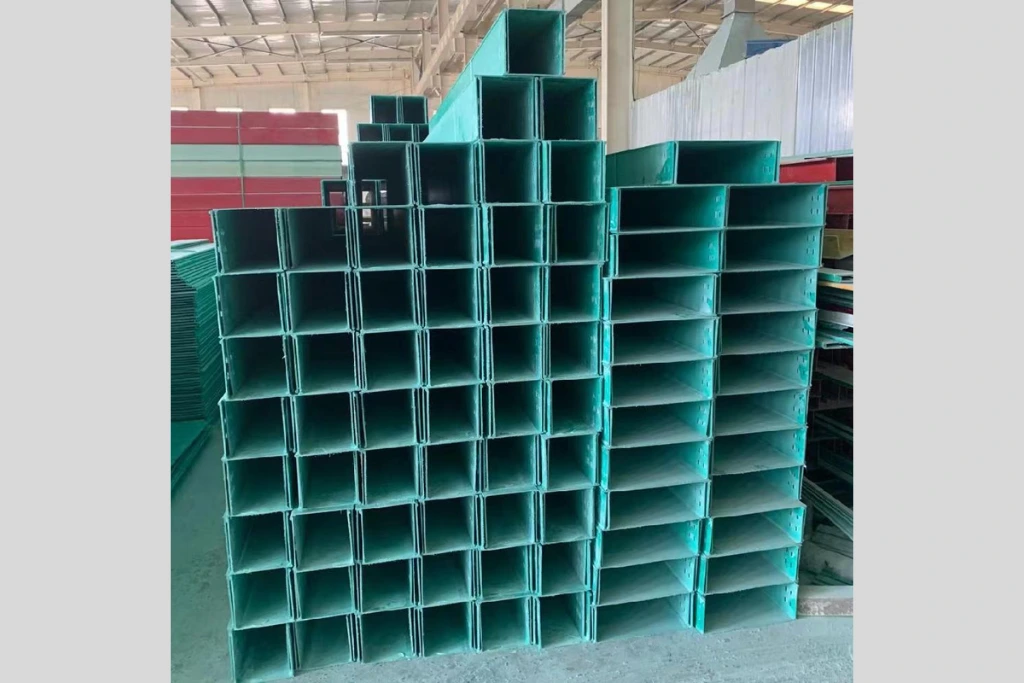

Why FRP Cable Troughs Are Gaining Popularity for Both Indoor and Outdoor Use

Across industries, FRP (Fiberglass Reinforced Plastic) cable troughs are increasingly becoming the material of choice because they offer:

- Complete corrosion resistance: No rust, even in chemical plants or coastal zones.

- Electrical non-conductivity: Safer installation around power systems.

- Lightweight strength: Easier and cheaper to install without compromising durability.

- Low maintenance: Saves money and effort over the trough’s lifespan.

- Customizability: Tailored shapes, sizes, and color options.

Whether indoors or outdoors, FRP provides an ideal balance between performance, cost, and long-term reliability.

Common Mistakes to Avoid in Cable Trough Projects

- Underestimating environmental stress: Outdoor environments require heavy-duty, UV- and corrosion-resistant materials.

- Overloading the trough: Always allow extra space for air circulation and future cable additions.

- Ignoring access requirements: If frequent maintenance is expected, choose troughs with easy-to-open lids.

- Failing to plan for expansion: Projects grow — selecting the right modular system upfront prevents costly replacements later.

A cable trough is more than just a pathway for wires — it’s a critical part of protecting infrastructure, ensuring system reliability, and maintaining safety standards.

Indoor and outdoor environments impose very different demands on cable management systems, so choosing the correct material, size, and design is crucial. For harsh outdoor conditions, corrosion-resistant materials like FRP or stainless steel are key. Indoors, lighter, more flexible systems like FRP often suffice, especially for fast-developing industries in Vietnam.

Whether your project in Vietnam involves a tech campus, a solar farm, a rail line, or an industrial facility, making the right choice for your cable trough system ensures long-term efficiency, safety, and peace of mind.

Looking for high-quality, expertly designed cable trough solutions in Vietnam? Contact The Front today – your trusted partner in advanced cable management systems.