The pultrusion process is one of the most reliable composite manufacturing methods for producing continuous FRP structural profiles with stable mechanical performance. Unlike batch-based fabrication techniques, pultrusion allows manufacturers to create uniform, fiber-reinforced components that maintain consistent strength, geometry, and durability over long lengths.

At THE FRONT, the pultrusion process is applied to manufacture structural FRP profiles used in industrial and construction environments where corrosion resistance, lightweight performance, and long service life are essential. Through its STRONX product line, THE FRONT delivers pultruded profiles engineered for demanding applications.

What Is the Pultrusion Process?

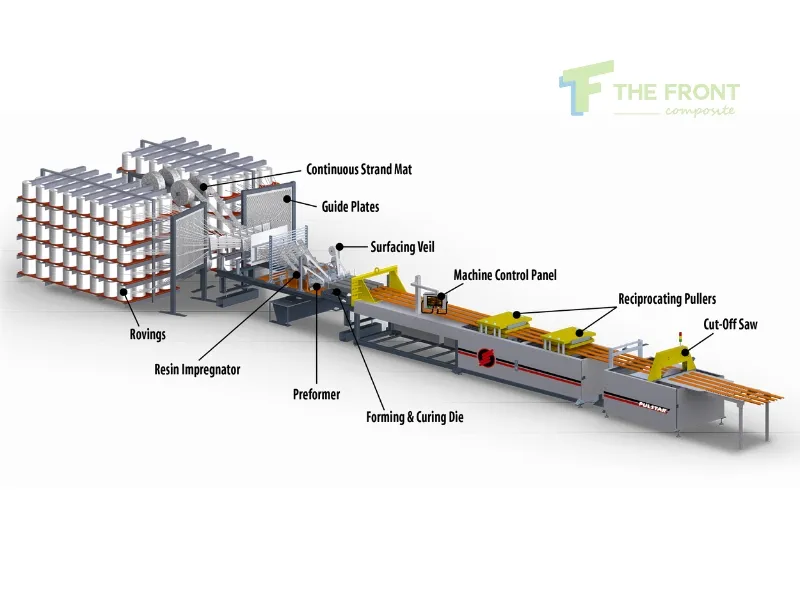

The pultrusion process is a continuous manufacturing method used to produce fiber-reinforced polymer profiles with constant cross-sections.

In this process, reinforcing fibers are pulled rather than pushed through a resin system and a heated forming die. The fibers become fully impregnated with resin, shaped, and cured into a rigid composite profile. Because the process is continuous, pultrusion ensures consistent material quality and repeatable mechanical performance.

This manufacturing approach is especially suitable for structural profiles that require predictable strength and dimensional stability over long spans.

Why THE FRONT Uses the Pultrusion Process for Structural FRP

THE FRONT applies the pultrusion manufacturing process because it delivers reliable structural performance with high production efficiency.

Pultrusion allows THE FRONT to control critical parameters such as fiber alignment, resin content, and curing conditions. This control results in pultruded FRP profiles that maintain strength, stiffness, and durability in environments where steel or aluminum structures often suffer from corrosion or fatigue.

By using pultrusion, THE FRONT ensures that each profile produced under the STRONX product line meets industrial requirements for long-term use.

Step-by-Step: How the Pultrusion Process Works

• Fiber reinforcement preparation

Continuous fiberglass rovings and mats are arranged and guided into the production line. The orientation of these fibers determines the mechanical strength of the final profile.

• Resin impregnation

The fibers pass through a resin system where they are fully saturated. The resin binds the fibers together and provides resistance to moisture, chemicals, and environmental exposure.

• Forming and curing

Impregnated fibers are pulled through a heated die that shapes the composite into a specific profile geometry. Heat initiates curing, converting the resin into a solid matrix that locks the fibers in place.

• Continuous pulling and cutting

Once cured, the rigid profile is continuously pulled forward and cut into required lengths. This ensures uniformity across all produced sections.

Each step contributes to consistent quality and structural reliability.

Pultrusion Process Machines and Production Stability

The pultrusion process machine plays a central role in maintaining consistency and precision.

Stable pulling speed, controlled resin flow, and accurate temperature regulation ensure that each profile cures evenly and retains dimensional accuracy. These controls minimize internal stress and prevent deformation during and after production.

At THE FRONT, pultrusion machines are operated under carefully managed conditions to ensure:

- Uniform fiber distribution

- Stable cross-sectional geometry

- Consistent surface quality

- Predictable mechanical behavior

This stability is essential for structural applications that require long-term performance.

Pultrusion Technology and Material Performance

Pultrusion technology enhances FRP material performance by aligning fibers along the load-bearing direction.

Because fibers run continuously along the length of the profile, pultruded FRP components exhibit strong tensile and flexural properties. This makes them suitable for beams, channels, purlins, and structural frames that must support static and dynamic loads.

The resin matrix protects fibers from environmental degradation, allowing pultruded profiles to perform reliably in humid, corrosive, or outdoor conditions without requiring frequent maintenance.

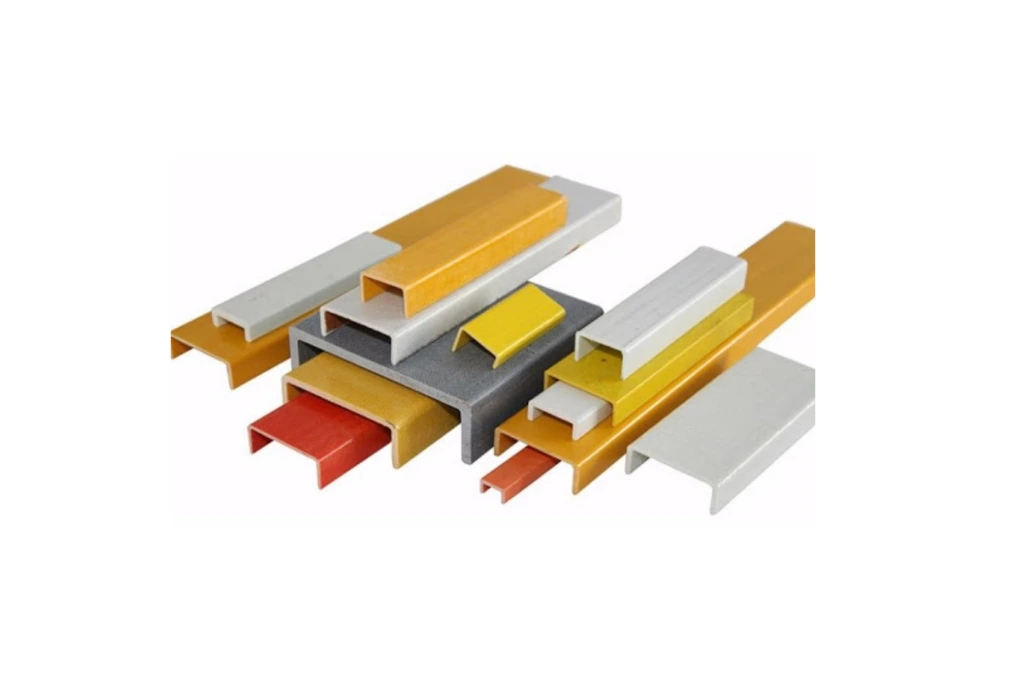

Production of Pultruded Profiles at THE FRONT

The production of pultruded profiles at THE FRONT focuses on structural consistency and durability.

Through its STRONX product line, THE FRONT manufactures a variety of FRP structural shapes used in industrial and construction projects. These profiles are designed to support platforms, walkways, roof systems, and structural frames where lightweight and corrosion-resistant materials are required.

The continuous nature of the pultrusion process allows THE FRONT to supply profiles with consistent quality across large production volumes, supporting both domestic and international projects.

Advantages of the Pultrusion Process in Industrial Applications

The pultrusion process offers several advantages over traditional fabrication methods.

• High strength-to-weight ratio

Pultruded FRP profiles provide strong structural performance while remaining lightweight, simplifying transportation and installation.

• Corrosion resistance

FRP profiles resist moisture, chemicals, and salt exposure, making them suitable for harsh industrial environments.

• Dimensional consistency

Continuous production ensures uniform cross-sections and stable geometry across long profile lengths.

• Low maintenance requirements

Pultruded FRP does not rust or require protective coatings, reducing long-term operational costs.

These advantages make pultruded profiles ideal for industrial facilities seeking durable structural solutions.

STRONX – Pultruded FRP Product Line of THE FRONT

STRONX is the pultruded FRP structural product line developed by THE FRONT to serve industrial and construction applications.

STRONX profiles are manufactured using controlled pultrusion processes to ensure:

- Stable mechanical strength

- Consistent dimensions

- Resistance to environmental exposure

- Suitability for long-term industrial use

Through STRONX, THE FRONT supports engineers and contractors who require dependable composite materials for structural systems.

Why the Pultrusion Process Matters for Long-Term Structural Performance

The pultrusion process directly influences the durability and reliability of FRP structural profiles.

Consistent fiber alignment and controlled curing reduce the risk of weak points or premature failure. This makes pultruded FRP components suitable for applications where long service life and minimal maintenance are critical.

For industrial projects operating under constant load or exposure to harsh environments, pultrusion offers a manufacturing solution that balances performance, efficiency, and reliability.

The pultrusion process used by THE FRONT enables the production of high-quality FRP structural profiles with stable mechanical properties and long-term durability. By combining continuous fiber reinforcement with controlled resin systems and precise manufacturing conditions, pultrusion delivers lightweight and corrosion-resistant solutions for industrial engineering.

Through its STRONX product line, THE FRONT applies pultrusion technology to support global projects requiring reliable composite structures. As industries continue to demand durable, low-maintenance materials, the pultrusion process remains a core manufacturing method for high-performance FRP solutions.