In modern industrial construction, material selection directly affects structural performance, durability, and long-term maintenance costs. Fiberglass Reinforced Polymer (FRP) has increasingly replaced traditional materials in demanding environments due to its corrosion resistance and lightweight properties. Within this material category, FRP structural shapes produced through pultrusion provide standardized, reliable building blocks that support efficient engineering design and industrial scalability.

Through its STRONX pultruded product line, THE FRONT manufactures a comprehensive range of FRP structural shapes, supporting industrial projects and export markets that require consistency, performance stability, and long service life.

What Are FRP Structural Shapes and Why They Matter

FRP structural shapes are pultruded profiles with constant cross-sections designed for load-bearing and structural applications.

These profiles are manufactured using continuous glass fiber reinforcement combined with thermoset resin systems. The result is a composite material that maintains predictable mechanical behavior while resisting corrosion, moisture, and many industrial chemicals.

For engineers, FRP structural shapes simplify structural planning. Instead of designing custom components for every application, standardized profiles allow designers to focus on load paths, connections, and system performance with greater confidence.

Design Flexibility Enabled by Pultruded FRP Profiles

Pultruded FRP structural profiles combine standardization with design flexibility.

The pultrusion process produces profiles with uniform geometry along their entire length. This consistency allows engineers to select specific shapes—beams, channels, angles, or tubes—based on structural function rather than manufacturing limitations.

Design flexibility is especially valuable in industrial facilities and warehouses, where modular construction, fast installation, and future expansion are important considerations. Lightweight FRP profiles reduce structural dead load, simplify handling, and allow efficient assembly without compromising strength.

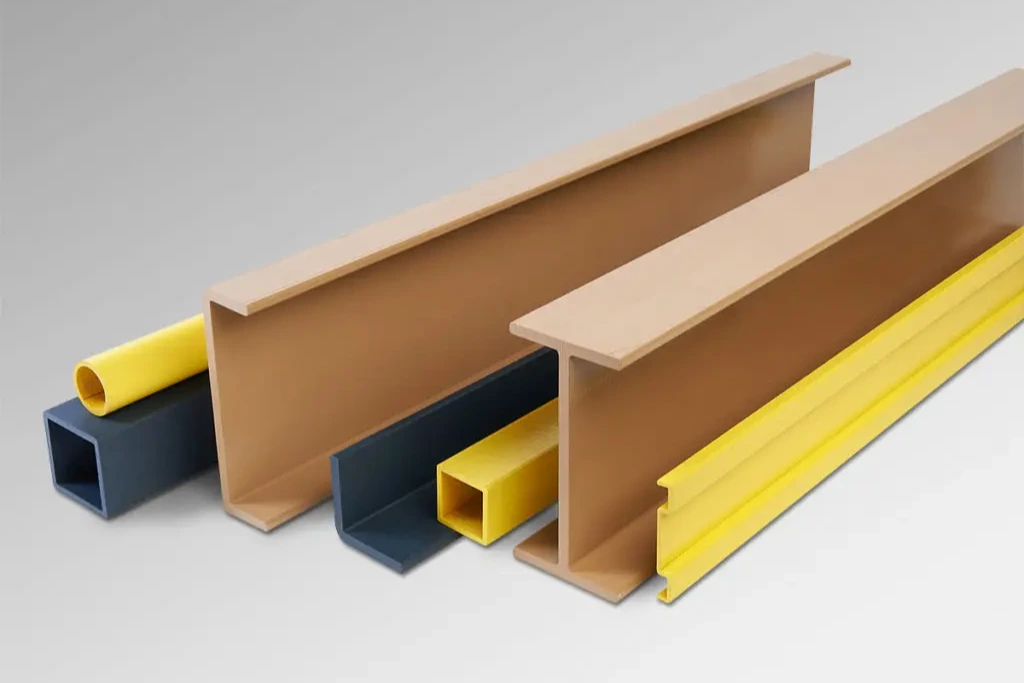

Overview of Common FRP Structural Shapes

FRP structural shapes are available in multiple standardized geometries, each serving a distinct engineering role.

These shapes are often presented through product drawings and infographics to support technical understanding and specification.

Pultruded FRP I beams

Used for primary load-bearing applications, FRP I beams provide high bending strength while remaining significantly lighter than steel.

Pultruded FRP C channels

Common in secondary framing, bracing systems, and support structures where alignment and ease of installation are critical.

FRP angles

Used for joint reinforcement, edge framing, and structural detailing within composite frameworks.

Square and rectangular FRP tubes

Closed-section profiles offering balanced strength in multiple directions, suitable for columns, frames, and modular structures.

Round FRP tubes

Often applied in railings, lightweight frameworks, and support systems where uniform stress distribution is required.

FRP purlins and fiberglass purlins

FRP anti-corrosion purlins are widely used in industrial roofing systems. Unlike steel, they do not rust or require protective coatings, making them suitable for humid and chemically aggressive environments.

Clear visualization of these shapes helps engineers and buyers quickly understand how each profile fits into a complete structural system.

Engineering Value of FRP Structural Shapes

The engineering value of FRP structural shapes lies in their performance stability and environmental durability.

Pultruded FRP profiles offer a high strength-to-weight ratio, reducing foundation loads and easing transportation and installation. This advantage is particularly important in elevated structures, retrofitting projects, and large-span roofs.

In addition, FRP is electrically non-conductive and corrosion resistant. These properties support safe use in chemical plants, electrical facilities, and industrial environments where moisture or aggressive substances are present. Over time, reduced corrosion risk translates into lower maintenance and lifecycle costs.

Industry References: Pultrusion Lines and Structural Standards

Within the global composite industry, pultrusion technology continues to evolve toward higher precision and production stability.

In technical discussions, arrow pultrusion is often referenced as a concept associated with optimized fiber alignment and continuous profile consistency. Such references highlight industry efforts to improve dimensional control and material repeatability in pultruded FRP profiles.

Similarly, EN 13706 European standards are widely cited as a classification framework for pultruded FRP structural shapes. These standards help engineers describe profile categories, typical applications, and general performance expectations when comparing composite structures across different markets.

These references provide useful industry context without being tied to any single manufacturer.

Application of FRP Structural Shapes in Roofing and Industrial Frameworks

FRP structural shapes are widely applied in industrial roof frames and warehouse structures.

FRP purlins and beams support roofing systems exposed to humidity, chemical vapors, and temperature variations. Unlike steel, FRP does not suffer from rust-related degradation, ensuring consistent performance over long service periods.

In warehouse and factory structures, FRP beams and columns enable lightweight frameworks that are easy to assemble and maintain. This makes FRP structural shapes suitable for industrial projects focused on durability, safety, and operational efficiency.

Product Visualization and Infographic-Based Communication

Infographic-based presentation plays a key role in communicating the value of FRP structural shapes.

By clearly illustrating profile geometry, dimensions, and structural function, infographics help engineers and procurement teams quickly evaluate product suitability. Visual comparison between FRP shapes and traditional materials also highlights advantages such as reduced weight, corrosion resistance, and lower maintenance needs.

For international buyers, clear product visualization supports faster specification, approval, and purchasing decisions.

THE FRONT and the STRONX Pultruded Product Line

THE FRONT manufactures FRP structural shapes through its STRONX pultruded composite product line.

STRONX profiles are produced using controlled pultrusion processes to ensure consistent geometry and stable mechanical performance. The product range includes beams, channels, angles, tubes, and purlins designed for industrial frames, roofing systems, and support structures.

As a pultruded FRP purlins manufacturer and supplier of structural profiles, THE FRONT focuses on production stability, material reliability, and export-oriented supply.

Manufacturing Capability and Export Readiness

Manufacturing consistency and export capability are essential for supplying FRP structural shapes to global markets.

THE FRONT operates pultrusion lines capable of continuous production with uniform quality, supporting large-volume orders and repeat supply. Careful handling, packaging, and logistics coordination ensure that FRP profiles reach overseas customers in optimal condition.

This export readiness allows THE FRONT to serve international projects that require corrosion-resistant, lightweight, and dimensionally consistent structural materials.

FRP structural shapes provide a practical balance between design flexibility and engineering performance.

Through standardized pultruded profiles such as I beams, C channels, angles, tubes, and purlins, engineers can design lightweight, durable, and corrosion-resistant structures for industrial environments.

With its STRONX product line, THE FRONT delivers FRP structural shapes that support industrial roofing systems, warehouse frameworks, and support structures for global markets. By combining clear product presentation, stable manufacturing capability, and export-oriented supply, THE FRONT continues to strengthen its role as a reliable provider of pultruded FRP structural solutions.