Industrial environments demand materials that are strong, safe, and resistant to the hazards of daily operations. Walkways, catwalks, and platform surfaces are particularly critical areas these are the pathways workers use every day, often in environments with heavy machinery, chemicals, and exposure to weather. The choice of grating system directly impacts safety, operational efficiency, and long-term maintenance costs.

FRP grating systems have become the preferred solution for these applications, offering unmatched durability, slip resistance, and corrosion protection. By integrating grating composite FRP technology into walkways and platforms, facility managers can enhance safety standards while optimizing operational performance.

What is FRP Grating?

FRP grating is a structural panel made from Fiber Reinforced Polymer. It consists of a matrix of high-strength glass fibers embedded in a thermosetting resin, forming a rigid yet lightweight structure. This manufacturing method produces gratings that are non-corrosive, non-conductive, and capable of withstanding heavy loads while maintaining excellent slip resistance.

Two main types are widely used: molded FRP grating, which offers superior corrosion resistance and impact tolerance, and pultruded FRP grating, which provides higher stiffness and load capacity for long-span applications.

Why FRP Grating Outperforms Traditional Materials

Corrosion Resistance

In industries such as chemical processing, marine, and wastewater treatment, steel grating quickly degrades due to rust. FRP grating resists corrosion from salts, acids, and other aggressive agents, ensuring long-term safety and performance.

Slip Resistance for Worker Safety

Industrial accidents from slips and falls are common, especially in wet or oily conditions. FRP gratings are engineered with anti-slip surfaces either concave or grit-coated to maintain traction even in challenging environments.

Lightweight for Easy Installation

FRP weighs significantly less than steel while delivering comparable strength. This reduces handling risks during installation and allows for quicker assembly without heavy lifting equipment.

Electrical and Thermal Non-Conductivity

The non-conductive nature of FRP provides a critical safety advantage in electrical or high-voltage environments, reducing the risk of electric shock. It also insulates against temperature extremes, improving worker comfort and safety.

Low Maintenance and Long Service Life

Unlike metal, FRP does not require painting, galvanizing, or regular surface treatment. Its durability reduces downtime and maintenance budgets over the lifespan of the structure.

Applications in Walkways and Platform Surfaces

Industrial Walkways

FRP gratings provide safe, stable surfaces in manufacturing plants, warehouses, and processing facilities. They can be tailored to fit around machinery, support heavy foot traffic, and resist wear from equipment.

Access Platforms

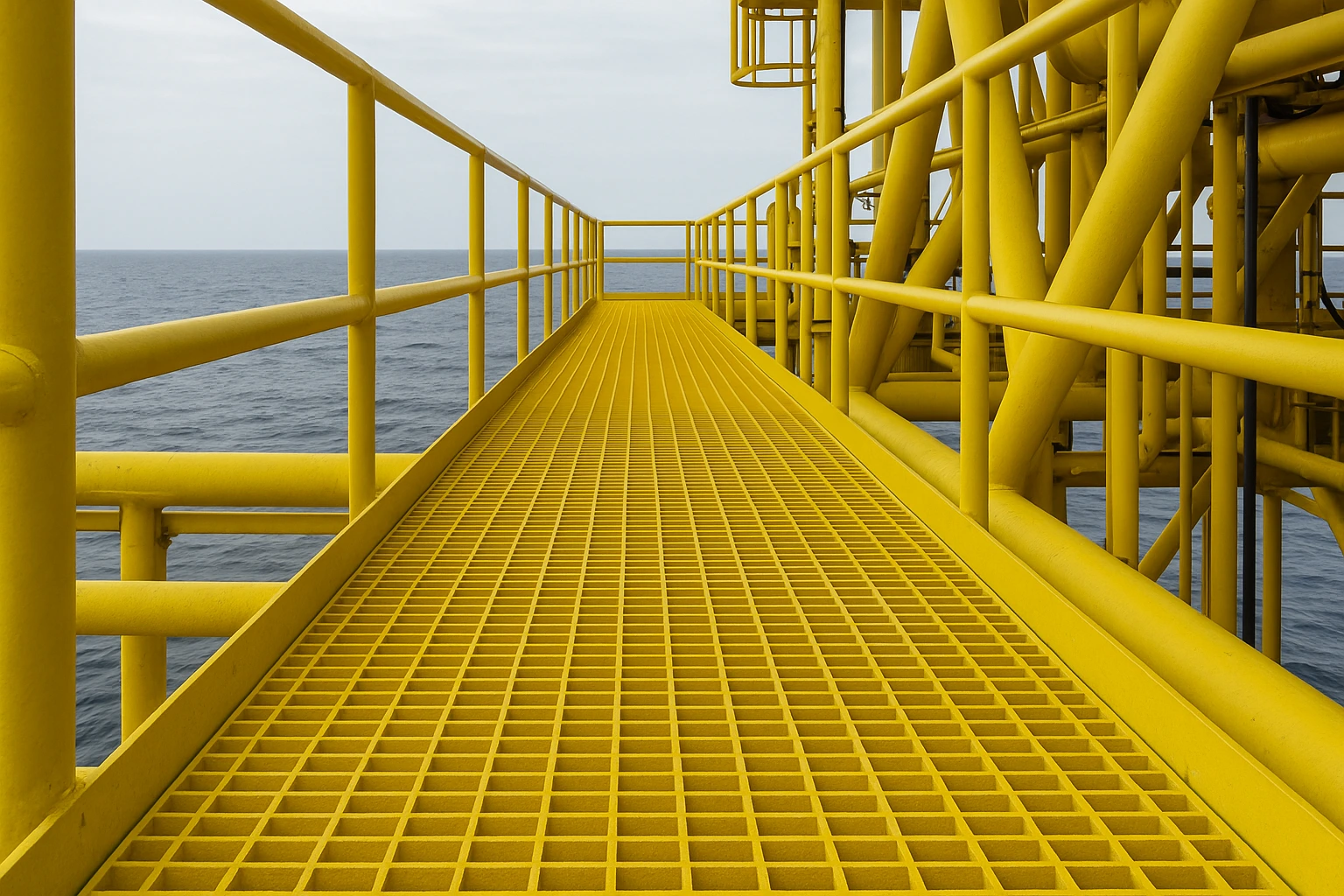

On elevated structures such as tanks, towers, and offshore rigs, FRP grating offers strength without adding unnecessary weight. Slip-resistant surfaces reduce the chance of falls in high-risk areas.

Maintenance Catwalks

In industries like water treatment or food processing, catwalks need materials that resist moisture and chemical exposure. FRP gratings perform reliably under these conditions while remaining easy to clean.

Marine and Offshore Decking

Saltwater exposure destroys unprotected metal in a short time. FRP grating remains unaffected by marine environments, making it ideal for docks, ship decks, and offshore platforms.

Design Considerations for FRP Grating Systems

Load Requirements

Choosing between molded and pultruded grating depends on the required load capacity and span length. Engineers should use manufacturer load tables for precise selection.

Surface Type

Grit-top surfaces provide maximum slip resistance, while concave tops are easier to clean. The right surface depends on the balance between safety and hygiene needs.

Fastening and Support

Proper clip systems and support structures ensure stability and prevent movement under load. FRP fasteners or stainless steel clips are commonly used for secure installation.

Open vs. Covered Grating

Open mesh gratings offer drainage and ventilation, while covered panels provide a continuous walking surface and prevent debris from falling through.

Sustainability and Long-Term Value

FRP grating systems contribute to sustainability goals by reducing resource consumption over their lifespan. Their durability minimizes replacement frequency, and many products are manufactured with processes that lower emissions.

The lightweight nature of FRP reduces transportation energy, while its resistance to environmental degradation ensures that it can remain in service for decades without performance loss.

Partnering with a Trusted Supplier

Selecting the right FRP grating is only part of the equation working with a knowledgeable supplier ensures the product matches the application. The Front specializes in delivering grating composite FRP solutions for industrial safety applications worldwide. From product selection and engineering guidance to international logistics, The Front provides the expertise and reliability necessary to achieve both safety compliance and operational efficiency.

By choosing a proven partner, facility managers can ensure that their walkway and platform surfaces are not only safe and durable but also cost-effective over the long term.

FRP grating systems have redefined safety and performance standards for industrial walkways and platform surfaces. Their combination of corrosion resistance, slip prevention, light weight, and low maintenance makes them an optimal choice for a wide range of industries.

With well-engineered designs, proper installation, and the support of trusted suppliers like The Front, companies can maximize safety, extend service life, and achieve long-term operational success.