Choosing the right FRP (Fiber Reinforced Plastic) manufacturer is crucial to ensuring that your project is supported by high-quality, durable, and reliable materials. Whether your project requires FRP panels, gratings, tanks, or custom FRP components, working with a trusted manufacturer can impact your project’s success and longevity. Here are the top five factors to consider when choosing an FRP manufacturer.

1. Expertise and Industry Experience

When selecting an FRP manufacturer, the first factor to consider is their level of experience in the industry. An established manufacturer with years of experience will have an extensive understanding of FRP production processes and a proven record of delivering high-quality products. Experienced manufacturers have also worked on diverse projects and applications, making them better equipped to understand unique requirements and provide tailored solutions.

Why It Matters: An experienced manufacturer is more likely to have the expertise to address specific project challenges and produce FRP products that meet demanding specifications. They can also advise on the best materials and design modifications to ensure your products are fit for purpose.

Tip: Research the manufacturer’s background and previous projects. Look for one that has a track record in your specific industry or application, as this demonstrates their ability to meet specialized needs.

2. Quality Control and Certifications

Quality control is a critical aspect of the manufacturing process, ensuring that each product meets high standards for strength, durability, and safety. When evaluating FRP manufacturers, look for those with robust quality control processes and relevant certifications, such as ISO certification. Certified manufacturers follow strict protocols to maintain consistent quality across their products, which can be essential in industries that require dependable, long-lasting materials.

Why It Matters: FRP products are often used in demanding environments where performance and safety are paramount. Working with a certified manufacturer with stringent quality control practices reduces the risk of product failure, ensuring that your project is built to last.

Tip: Ask potential manufacturers about their quality assurance protocols and certifications. Certifications from reputable industry organizations are a good indicator of a manufacturer’s commitment to quality and safety.

3. Customization Options and Product Range

Each project has its own unique requirements, so choosing an FRP manufacturer with a wide product range and customization options can provide significant advantages. Whether you need specific dimensions, custom colors, or specialized resins, a manufacturer capable of tailoring FRP products can ensure a closer fit to your project’s needs. Customization is especially valuable for projects in sectors like construction, marine, or industrial settings, where specific strength, size, and resistance characteristics may be necessary.

Why It Matters: A manufacturer with a wide range of customizable options can better meet your specifications, enhancing both the functionality and aesthetics of the FRP products used. This level of flexibility allows you to select a product that will integrate seamlessly into your design and meet project demands.

Tip: Ask manufacturers about their customization capabilities and product range. Ensure they have the flexibility to adjust characteristics like thickness, resin type, and surface texture, which can be essential for high-performance applications.

4. Customer Support and Technical Assistance

Responsive customer support and technical assistance can be invaluable throughout your project, from initial consultation to post-installation support. A manufacturer with strong customer support is more likely to offer technical guidance, answer questions, and address any concerns that may arise. This is especially important for complex installations or large projects where expert advice can prevent costly mistakes and ensure smooth project execution.

Why It Matters: Knowledgeable customer support can help you navigate product selection, installation techniques, and maintenance practices. This level of service not only enhances project efficiency but also adds value by offering peace of mind, knowing you have access to expert assistance.

Tip: When evaluating manufacturers, ask about their customer support structure. Look for a manufacturer that provides dedicated support, has accessible representatives, and offers technical assistance if needed.

5. Lead Time and Delivery Capability

Timely delivery of materials is crucial to keeping your project on schedule, so it’s essential to choose an FRP manufacturer with dependable lead times and delivery capabilities. A reliable manufacturer will be transparent about lead times, honor delivery commitments, and have efficient logistics in place. This factor becomes even more critical for large-scale or time-sensitive projects, where delays in receiving materials can disrupt workflow and increase costs.

Why It Matters: Delayed materials can lead to costly project interruptions and rescheduling challenges. Working with a manufacturer that has efficient production processes and delivery capabilities helps to keep your project on track and within budget.

Tip: Discuss lead times with the manufacturer early in the process. Ask about their ability to accommodate urgent requests or large orders, especially if you have a tight project timeline. Reliable delivery means peace of mind that you’ll receive the products when needed.

Why THE FRONT is a Trusted Partner for FRP Solutions

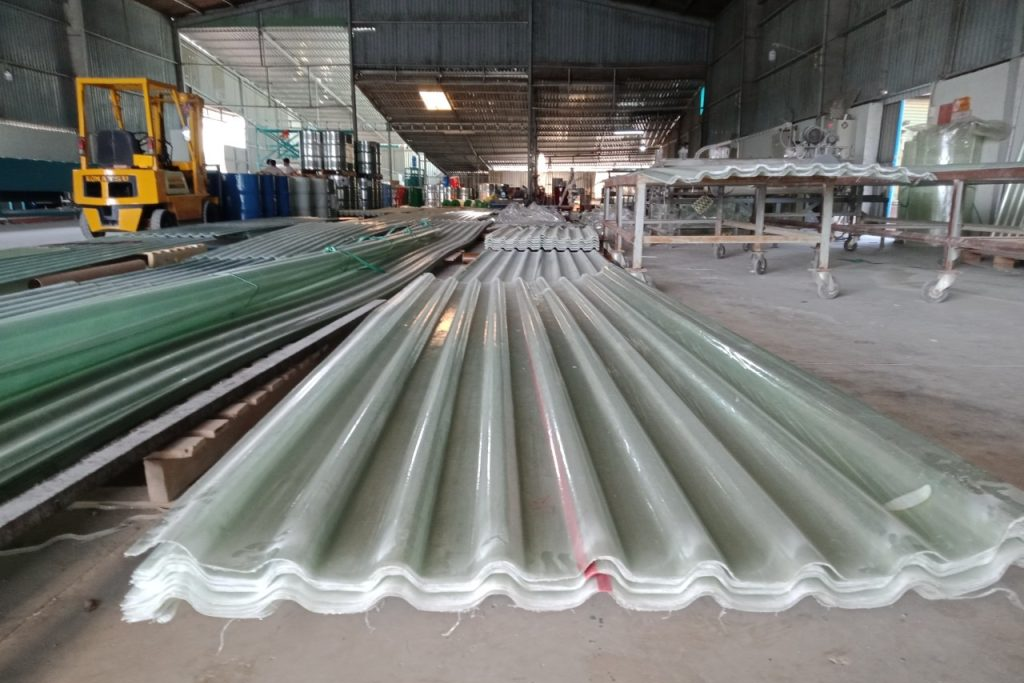

When it comes to choosing an FRP manufacturer, THE FRONT stands out as a trusted partner in the industry. With decades of experience, THE FRONT offers a wide range of FRP products, including panels, gratings, tanks, and roofing solutions, each produced to meet the highest quality standards. THE FRONT’s commitment to quality control is reflected in their certifications and rigorous testing processes, ensuring their products are durable, safe, and reliable.

THE FRONT provides extensive customization options, allowing clients to choose products tailored to specific project needs, from size and thickness to color and resin type. Their knowledgeable customer support team offers technical guidance and project insights, supporting clients throughout every phase. With dependable lead times and a reputation for timely delivery, THE FRONT ensures that your project stays on schedule.

For those seeking a reliable FRP manufacturer, THE FRONT combines industry expertise with customer-focused service, making them a valuable partner for any project.