In the modern era of engineering and construction, the demand for materials that combine light weight with high structural strength continues to grow. From large-scale bridges and industrial complexes to offshore platforms and commercial facilities, global projects now prioritize materials that deliver durability, energy efficiency, and cost-effectiveness without compromising design freedom.

Composite materials, particularly Fiber Reinforced Polymers (FRP), have proven to be a critical enabler of these priorities. Their unique combination of performance characteristics is helping project owners and design teams meet increasingly demanding requirements for structural integrity, environmental resilience, and operational efficiency.

Understanding Composite Materials

Composite materials are engineered by combining two or more constituent substances with distinct physical or chemical properties, resulting in a new material with enhanced performance. In structural engineering, one of the most widely used types is FRP, which integrates high-strength fibers such as glass, carbon, or aramid into a polymer resin matrix.

This fusion of reinforcement and resin creates materials that offer superior strength-to-weight ratios, resistance to corrosion, and the flexibility to be molded into a wide range of shapes and sizes. Unlike traditional metals or concrete, composite panels and FRP profiles can be tailored to specific performance requirements, making them ideal for specialized projects in diverse industries.

Advantages Driving Adoption in Global Projects

High Strength-to-Weight Ratio

A well-designed FRP component can match or even exceed the load-bearing capacity of steel at a fraction of the weight. This property reduces the need for heavy support structures, cuts transportation costs, and simplifies installation—factors that are especially valuable in remote or logistically challenging project sites.

Corrosion Resistance

One of the most significant advantages of composite panels and FRP structures is their resistance to corrosion. Unlike steel, which rusts, or concrete, which can degrade under chemical attack, FRP retains its integrity in marine, chemical, or high-humidity environments.

Design Flexibility

Composite materials can be molded into complex geometries, enabling innovative designs in both functional and aesthetic applications. This allows architects and engineers to explore solutions that would be difficult or impossible with conventional materials.

Low Maintenance and Longevity

The inherent durability of FRP significantly reduces maintenance requirements. Its resistance to UV radiation, impact, and weathering means fewer replacements and lower lifetime costs.

Thermal and Electrical Insulation

FRP is naturally non-conductive and can be engineered to provide thermal insulation, adding safety and efficiency benefits in power, telecommunications, and industrial facilities.

Key Applications of Composite Materials

Infrastructure and Civil Works

FRP is increasingly used in bridge decks, pedestrian walkways, and structural supports, where its light weight facilitates rapid installation and its corrosion resistance extends service life.

Industrial and Manufacturing Facilities

Composite panels serve as roofing, cladding, and wall systems in harsh industrial environments, providing protection against chemical exposure and moisture.

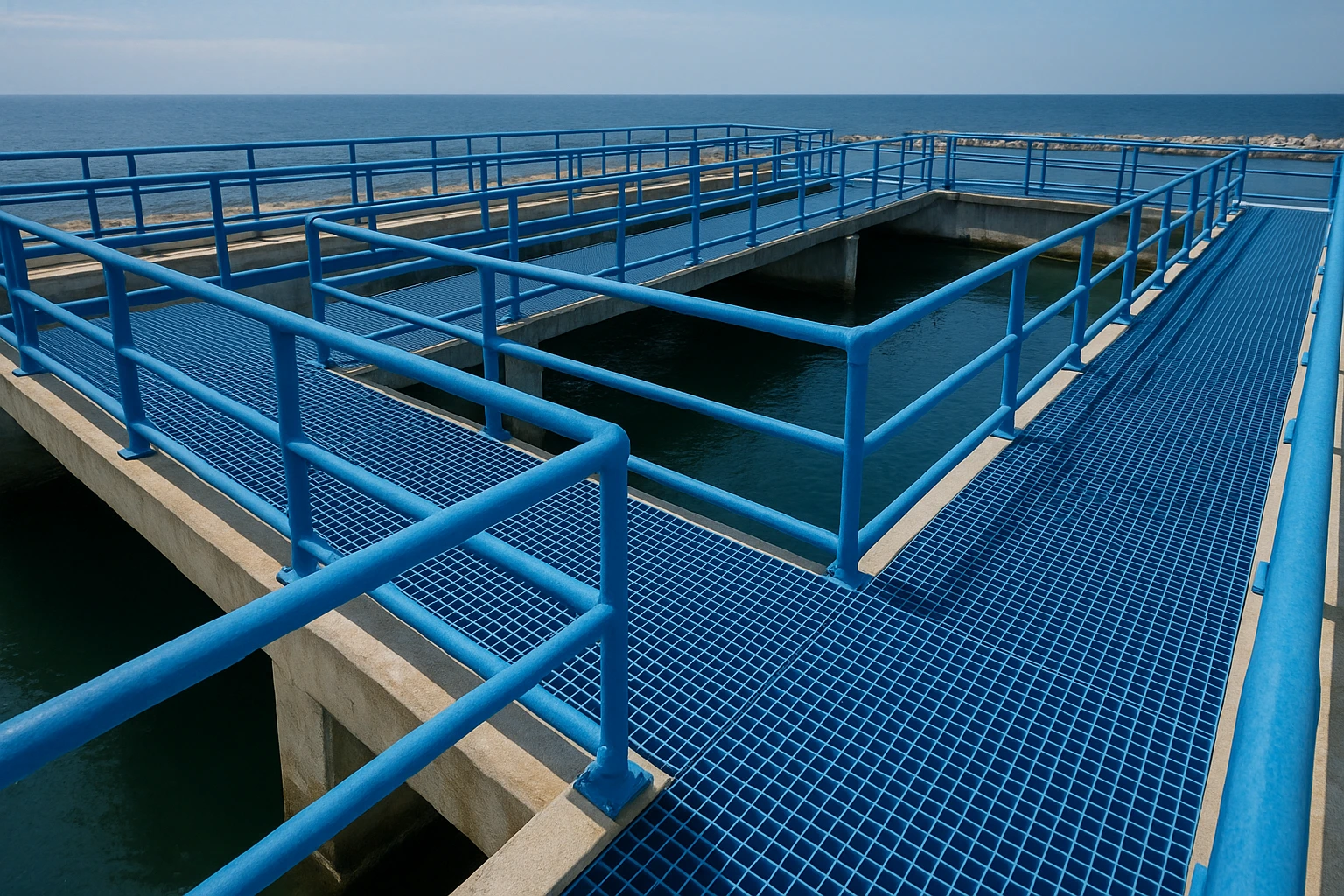

Marine and Offshore

Saltwater corrosion is a major threat to conventional materials. FRP components maintain structural integrity in ship decks, docks, and offshore platforms, making them a preferred choice in marine engineering.

Architectural and Commercial Spaces

From translucent canopies to curved façade elements, composite panels blend aesthetics with functionality, offering light transmission, weather protection, and creative design potential.

Transportation Systems

In rail, aerospace, and automotive industries, lightweight FRP structures reduce energy consumption while maintaining the necessary safety and performance standards.

Design and Engineering Considerations

Material Composition

Selecting the right fiber type, resin system, and manufacturing method is essential for achieving optimal performance. Glass fibers are cost-effective, carbon fibers deliver higher stiffness, and aramid fibers excel in impact resistance.

Structural Analysis

Composites are anisotropic—meaning their strength varies with fiber orientation so accurate engineering models are critical to ensuring safety and reliability under load.

Connections and Fastening

Unlike metals, composites require specific joining methods to avoid stress concentration. Adhesive bonding, bolted joints with load-spreading plates, or integrally molded connectors are common.

Environmental Durability

Temperature extremes, UV exposure, and moisture conditions must be factored into design specifications to ensure the structure performs consistently over time.

Sustainability Benefits

The environmental advantages of composite materials go beyond performance. Their long service life reduces the frequency of replacement, conserving resources and minimizing waste. Many FRP products are manufactured using low-VOC resins and can incorporate recycled fibers, aligning with green building standards.

Light weight also translates into lower transportation energy use and reduced carbon emissions, contributing to the sustainability goals of infrastructure and industrial projects worldwide.

Partnering with a Trusted Supplier

When implementing composite materials in global projects, sourcing from a reliable manufacturer ensures consistent quality and technical support. The Front is a leading supplier of FRP and composite panels for demanding applications around the world. From tailored design assistance to stringent quality control and efficient logistics, The Front delivers solutions that meet both the performance requirements and the project timelines of international clients.

By combining advanced engineering expertise with proven manufacturing processes, The Front helps customers achieve structures that are lighter, stronger, and built to withstand the challenges of diverse environments.

Composite materials – particularly FRP – are transforming the way engineers and architects approach structural design. Their unique combination of strength, light weight, and environmental resistance enables projects that are more efficient, sustainable, and innovative.

With the right design approach and the support of experienced suppliers like The Front, global projects can fully leverage the advantages of composite panels and FRP structures to achieve lasting performance and value.