When planning a construction project, selecting the right material is critical for long-term performance and cost-efficiency. FRP panels (Fiberglass Reinforced Plastic) have become a popular alternative to traditional materials like wood, steel, and aluminum due to their unique benefits. In this article, we compare FRP panels with these traditional materials to help you decide which is best for your project.

What Are FRP Panels?

FRP panels are composite materials made from a matrix of plastic reinforced with glass fibers. This combination offers an excellent strength-to-weight ratio, corrosion resistance, and versatility in various applications, from industrial facilities to commercial kitchens and bathrooms.

Key Comparisons: FRP Panels vs. Traditional Materials

1. Durability and Corrosion Resistance

- FRP Panels: One of the standout features of FRP panels is their exceptional resistance to corrosion, chemicals, and moisture. This makes them ideal for environments where exposure to harsh substances or humidity is common, such as wastewater treatment plants or food processing facilities.

- Traditional Materials: Materials like steel and wood are prone to corrosion and rot when exposed to moisture or chemicals. Steel requires protective coatings and regular maintenance to prevent rust, while wood can warp, decay, or become infested with pests.

2. Strength-to-Weight Ratio

- FRP Panels: Despite their lightweight nature, FRP panels provide excellent structural strength. They can replace heavy materials like steel in many applications, reducing transportation and installation costs while maintaining durability.

- Steel/Aluminum: Steel is strong but significantly heavier than FRP, leading to higher installation costs and greater strain on structures. Aluminum, while lighter, lacks the same impact resistance and can deform under pressure.

3. Thermal and Electrical Properties

- FRP Panels: FRP has low thermal conductivity, which makes it a better insulator than metals like steel or aluminum. This makes FRP suitable for environments where temperature stability is important. Additionally, FRP is non-conductive, making it safer for applications where electrical conductivity could pose a risk.

- Traditional Materials: Metals, on the other hand, are good conductors of heat and electricity, which can make them less desirable in environments where insulation and safety are key concerns.

4. Maintenance

- FRP Panels: One of the major benefits of FRP is its low maintenance requirements. Thanks to its resistance to corrosion, impact, and environmental factors, FRP panels typically require less frequent repairs or replacements compared to traditional materials.

- Traditional Materials: Steel and wood demand more maintenance. Steel needs periodic painting and inspection to prevent rust, and wood often requires treatments to protect against moisture and pests.

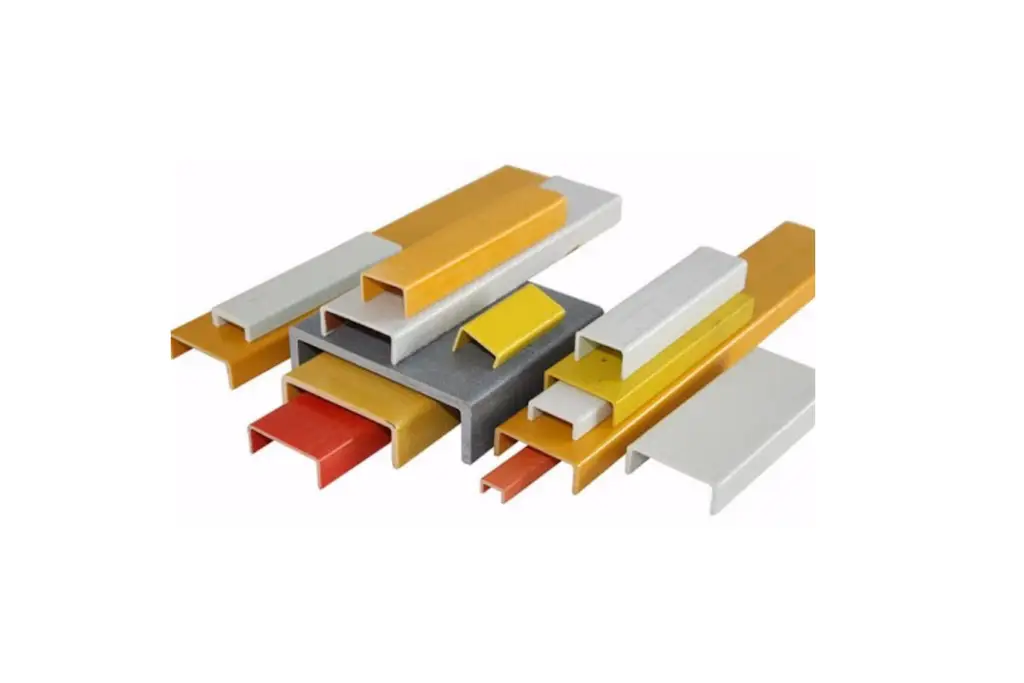

5. Customization

- FRP Panels: FRP panels are highly customizable. They can be manufactured in various sizes, colors, and finishes to suit specific project requirements. This flexibility is particularly beneficial in architectural design and industrial applications.

- Traditional Materials: While materials like wood can also be customized to some extent, they do not offer the same flexibility as FRP when it comes to integrating complex shapes or finishes without compromising performance.

Cost Comparison: Upfront vs. Long-Term Savings

- FRP Panels: While FRP panels can sometimes have a higher initial cost compared to materials like wood or aluminum, they offer significant long-term savings due to their durability, low maintenance, and longer lifespan. This makes them a cost-effective solution over time.

- Traditional Materials: Materials like steel and wood may have lower upfront costs but require ongoing maintenance, which increases long-term expenses. Additionally, their shorter lifespan compared to FRP may lead to more frequent replacements.

Environmental Benefits of FRP Panels

FRP panels contribute to sustainable construction practices due to their long lifespan and low maintenance needs. Their production often involves fewer resources than traditional materials, and they reduce the environmental impact associated with frequent replacements and repairs.

Conclusion: Which Is Best for Your Project?

Choosing between FRP panels and traditional materials depends on your project’s specific requirements. If your priority is long-term durability, resistance to corrosion, and reduced maintenance, FRP panels are an excellent choice, particularly in environments exposed to chemicals, moisture, or extreme temperatures. On the other hand, if your project has tighter upfront budget constraints and less exposure to harsh conditions, traditional materials like wood or steel may suffice.

Ultimately, for demanding industrial or commercial applications, FRP panels offer a more sustainable, cost-effective, and durable solution that can outperform traditional materials in the long run.