As industrial construction moves toward materials that are lightweight, corrosion-resistant, and easy to maintain, pultruded FRP tubes have become an important structural solution. Compared to traditional steel or aluminum tubes, FRP tubes offer superior durability in harsh environments while reducing installation and lifecycle costs. This shift has increased demand for reliable manufacturers capable of delivering consistent composite tube profiles for both domestic and international projects.

As a FRP tube manufacturer in Vietnam, THE FRONT supplies pultruded FRP tubes through its STRONX product line, supporting industrial structures, infrastructure projects, and export markets that require stable quality and dependable performance.

What Are Pultruded FRP Tubes?

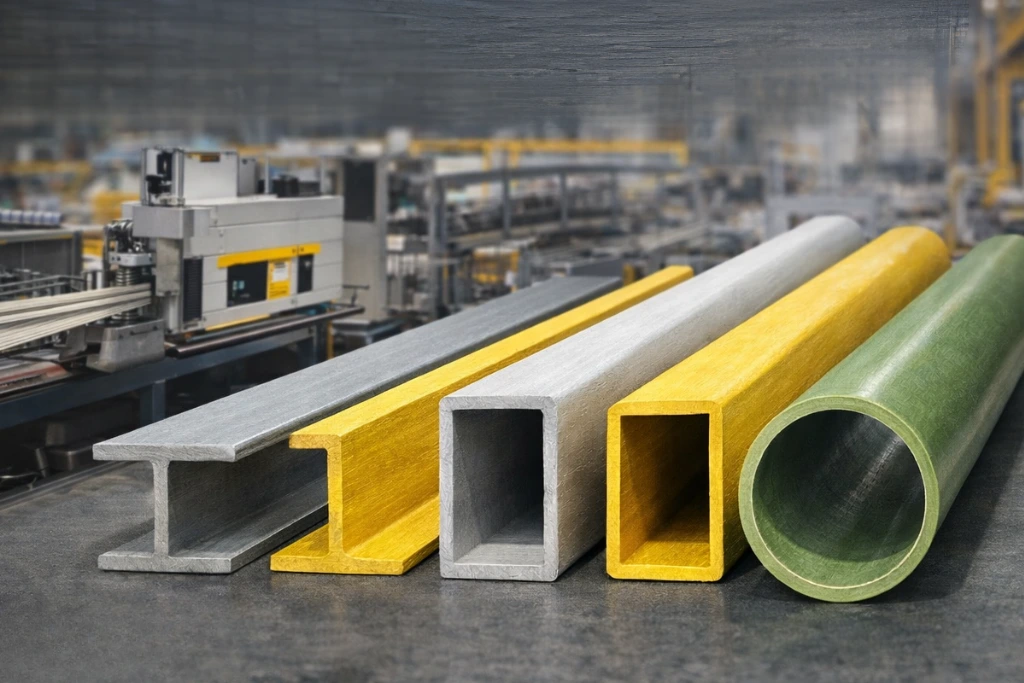

Pultruded FRP tubes are closed-section composite profiles produced using a continuous pultrusion process.

They are reinforced with continuous glass fibers embedded in a thermoset resin matrix, resulting in a lightweight yet structurally stable profile. Because of their closed geometry, FRP tubes provide balanced strength in multiple directions, making them suitable for columns, frames, and load-distribution structures.

FRP tubes resist corrosion, moisture, and chemical exposure, allowing them to perform reliably in environments where metal tubes degrade quickly.

Why FRP Tubes Are Increasingly Used in Industrial Structures

FRP tubes address many limitations of conventional tubular materials.

In industrial environments, steel tubes often require coatings, regular inspection, and corrosion protection. FRP tubes eliminate these issues by offering inherent resistance to rust and chemical attack.

Key advantages include:

- Lightweight structure that simplifies transportation and installation

- High strength-to-weight ratio

- Electrical non-conductivity

- Low maintenance over long service periods

- Stable performance in humid or corrosive environments

These properties make FRP tubes suitable for factories, warehouses, processing plants, and infrastructure systems.

Pultrusion Process and Tube Geometry Consistency

The pultrusion process ensures uniform cross-section and predictable mechanical behavior.

During production, continuous fibers are pulled through a resin system and shaped within a heated die. This process produces FRP tubes with constant wall thickness, straight geometry, and consistent material properties along their entire length.

For engineers and contractors, this consistency is critical. It allows FRP tubes to be specified with confidence, especially for structural frames and modular systems where dimensional accuracy matters.

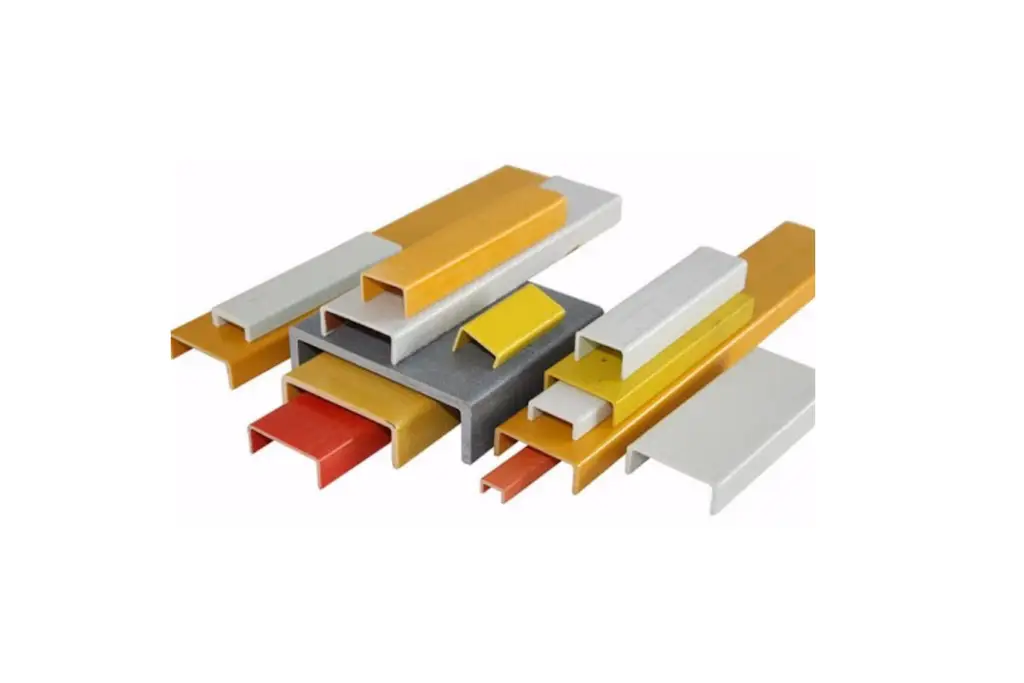

Types of FRP Tubes Supplied for Industrial Applications

FRP tubes are available in multiple standard geometries to support different structural needs.

Square FRP tubes

Provide balanced stiffness and torsional resistance, commonly used in columns, frames, and modular structures.

Rectangular FRP tubes

Offer directional strength, suitable for beams, supports, and structural frames where bending occurs primarily in one direction.

Round FRP tubes

Deliver uniform stress distribution and are widely used in handrails, support systems, and lightweight frameworks.

These standardized tube profiles allow engineers to design complete structural systems using consistent composite materials.

Engineering Value of FRP Tubes in Load-Bearing Systems

The engineering value of FRP tubes lies in their structural efficiency and environmental durability.

Closed-section FRP tubes provide good resistance to buckling and torsion while remaining significantly lighter than steel. This reduces overall structural weight and simplifies foundation design.

FRP tubes are also suitable for environments requiring electrical insulation or corrosion resistance, such as chemical plants, wastewater facilities, and industrial zones with high humidity or aggressive substances.

Vietnam as a Growing Base for FRP Tube Manufacturing

Vietnam has become an increasingly important manufacturing base for pultruded FRP profiles.

Local manufacturers benefit from established composite production expertise, stable labor resources, and growing export infrastructure. This allows Vietnamese factories to supply high-quality FRP profiles at competitive cost levels.

As a pultrusion factory in Vietnam, THE FRONT operates production lines capable of delivering consistent FRP tube profiles for industrial and overseas markets.

THE FRONT as a High-Quality FRP Profiles Supplier in Vietnam

THE FRONT positions itself as a high-quality FRP profiles supplier in Vietnam by focusing on manufacturing stability and product consistency.

Through controlled pultrusion processes, THE FRONT produces FRP tubes with uniform geometry and reliable mechanical performance. This consistency supports large-scale industrial projects that require repeat supply and long-term material stability.

By maintaining production discipline and quality control, THE FRONT supports customers seeking dependable composite tube solutions.

Competitive Export Capability and Global Supply

Competitive FRP profiles export prices from Vietnam make FRP tubes an attractive option for international buyers.

Beyond pricing, export readiness is critical. FRP tubes must be properly handled, packaged, and transported to ensure they arrive at project sites in usable condition.

THE FRONT supports export projects by coordinating production scheduling, packaging, and logistics for overseas delivery. This allows international customers to source FRP tubes from Vietnam with confidence in quality and delivery reliability.

STRONX – Pultruded FRP Tube Product Line of THE FRONT

STRONX is the pultruded FRP product line developed by THE FRONT for industrial structural applications.

STRONX FRP tubes are designed for use in frames, columns, supports, and structural systems that require lightweight and corrosion-resistant materials. The product line includes square, rectangular, and round tube profiles suitable for various engineering requirements.

By offering standardized tube profiles, STRONX supports efficient structural design and modular construction approaches.

Applications of FRP Tubes in Industrial Structures

FRP tubes are widely used across industrial sectors.

Common applications include:

- Structural frames for factories and warehouses

- Support columns and modular systems

- Equipment support structures

- Handrail and safety systems

- Industrial enclosures and auxiliary frameworks

These applications benefit from FRP’s durability, low maintenance, and long service life.

Pultruded FRP tubes provide a practical combination of lightweight performance, structural stability, and corrosion resistance.

As industrial projects demand materials that reduce maintenance and improve durability, FRP tubes continue to replace traditional metal solutions.

As a FRP tube manufacturer in Vietnam, THE FRONT, through its STRONX product line, supplies pultruded FRP tubes engineered for industrial structures and global markets. With stable manufacturing capability, consistent quality, and export readiness, THE FRONT supports international clients seeking reliable composite tube solutions for long-term structural performance.