FRP (Fiberglass Reinforced Polymer) has become one of the most important composite materials used in industrial and infrastructure applications. As industries shift toward lightweight, corrosion-resistant, and low-maintenance materials, advancements in FRP technology have been essential in improving consistency, performance, and production efficiency. Modern FRP manufacturing processes give producers the ability to deliver stable material quality at scale, enabling FRP products to meet the demands of harsh operating environments.

Manufacturers like THE FRONT apply a range of FRP production methods including Hand Lay-up, Light RTM, Spray-up, and controlled continuous panel manufacturing to create dependable composite roofing sheets, translucent panels, and industrial components.

The Evolution of FRP Technology in Industrial Manufacturing

FRP technology defines the methods, materials, and production controls used to create fiberglass-reinforced composites with long-term durability.

Advances in FRP manufacturing have transformed how materials perform under extreme weather, corrosive chemicals, or continuous loading.

Modern FRP technology focuses on:

- More stable resin systems

- Better fiber distribution

- Improved surface protection through gelcoats

- Enhanced dimensional accuracy in large-volume production

- Consistent manufacturing cycles to ensure repeatable quality

As a result, today’s FRP panels and components demonstrate higher strength, better UV resistance, and superior outdoor durability compared with earlier-generation composites.

FRP Production Process: Foundation of Material Quality

The FRP production process determines how fibers and resin interact to create a strong, consolidated composite.

Each manufacturing method results in different surface characteristics, mechanical performance, and production efficiency.

During fabrication, glass fibers provide reinforcement, while resin acts as a protective matrix that bonds the structure together and resists corrosion. The combination of fiber architecture and resin quality determines the final strength and stability of the composite panel or profile.

Key factors that influence FRP performance include:

- Fiber alignment and layer structure

- Resin impregnation and curing quality

- Gelcoat selection for UV and weathering resistance

- Control of temperature, pressure, and production timing

Well-controlled production not only improves product longevity but also reduces the need for maintenance.

Modern FRP Production Lines: Precision and Efficiency at Scale

An FRP production line is designed to control material thickness, curing behavior, and cross-sectional accuracy.

Precise equipment settings such as resin flow rate, reinforcement tension, and temperature ensure consistent panel quality throughout the entire production cycle.

Modern FRP production lines enhance performance by enabling:

- Uniform thickness across long panel lengths

- Stable curing that reduces surface defects and internal stress

- Smooth gelcoated surfaces suitable for outdoor roofing applications

- Efficient mass production with reduced variability

THE FRONT’s production capability allows consistent output of translucent roofing panels, anti-corrosion FRP sheets, and other composite materials used across industrial facilities.

Hand Lay-Up: Versatile Production for Custom FRP Components

Hand Lay-up is a traditional yet essential FRP manufacturing process, ideal for customized shapes and low-volume production.

In this method:

- Reinforcement layers are manually placed

- Resin is applied by brush or roller

- Air is removed to improve bonding

- The laminate cures at controlled temperature

Advantages include:

- Flexibility for large or complex shapes

- Good control of reinforcement placement

- Suitable for custom FRP components used in industrial settings

This process remains widely used because of its adaptability in both small-batch manufacturing and structural repairs.

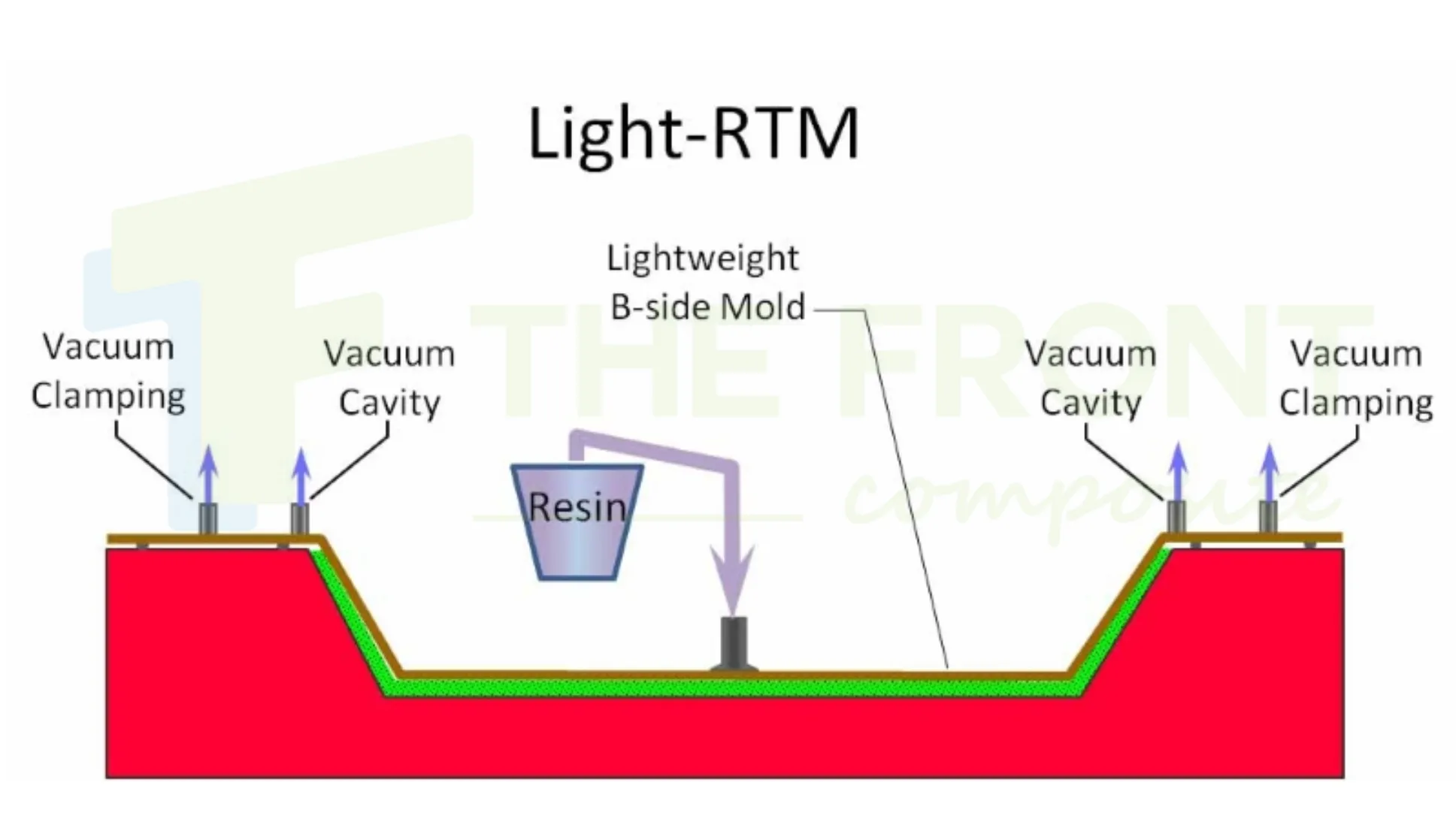

Light RTM Technology: Improved Surface and Dimensional Control

Light Resin Transfer Molding (LRTM) is a closed-mold process that enhances surface finish, material uniformity, and resin penetration.

Key benefits include:

- Smooth surface finish on both sides of the panel

- More consistent fiber-to-resin ratio

- Better thickness control

- Cleaner production environment

LRTM is well-suited for FRP roofing sheets, translucent panels, and composite components requiring visual uniformity and long-term stability in outdoor environments.

Spray-Up: Efficient Manufacturing for Curved or Complex Surfaces

Spray-up technology combines chopped fiberglass and resin that are deposited simultaneously onto a mold surface.

It offers:

- High production efficiency

- Good coverage for curved, contoured, or large surfaces

- Flexibility in thickness adjustment

Spray-up is ideal for industrial composite parts that require moderate strength and adaptable geometry. The method also reduces production time compared with manual lay-up.

RTM Technology: Closed-Mold Precision for Enhanced Structural Integrity

Resin Transfer Molding (RTM) is a closed-mold process that provides excellent dimensional accuracy and predictable structural performance.

RTM enhances composite quality through:

- Controlled resin injection

- Thorough fiber wet-out inside the mold

- Reduced void formation

- Improved structural consistency

The resulting FRP components demonstrate long-term stability and reliable performance in corrosive or moisture-exposed environments.

How Modern FRP Technology Improves Material Performance

Modern FRP manufacturing technologies improve composite behavior through enhanced resin chemistry, reinforcement architecture, and curing precision.

• Higher mechanical strength

Fiber alignment and controlled resin wet-out result in stable tensile and flexural performance.

• Improved corrosion resistance

Resin systems protect fibers from water, chemicals, and environmental degradation.

• Better UV and weathering durability

Gelcoated surfaces enhance resistance to sunlight and outdoor conditions.

• More stable dimensional accuracy

Consistent curing produces predictable thickness and profile geometry.

• Longer service life with minimal maintenance

FRP products retain their properties without requiring repainting or anti-corrosion treatment.

These advantages make modern FRP technology a dependable solution for factories, warehouses, industrial plants, and infrastructure systems.

THE FRONT’s Expertise in FRP Manufacturing Processes

THE FRONT applies advanced FRP technology and controlled production processes to produce durable composite materials for industrial use.

Its capabilities include:

- Hand lay-up for custom FRP components

- Light RTM technology for smooth, dimensionally consistent panels

- Spray-up for efficient production of curved or complex shapes

- Controlled continuous production of FRP roofing and translucent panels

By combining process control with material expertise, THE FRONT ensures that every FRP product delivered to industrial clients meets strict requirements for durability, appearance, and long-term performance.

Modern FRP technology plays a critical role in enhancing material precision, production efficiency, and structural performance. With improved manufacturing processes such as Hand Lay-up, Light RTM, Spray-up, RTM, and controlled FRP production lines, composite materials now offer the durability and consistency required for industrial environments.

Through advanced manufacturing experience and stable production capability, THE FRONT provides FRP products engineered to perform reliably in demanding applications across global markets. As industries continue to adopt composite solutions, FRP technology will remain an essential foundation for producing high-quality, long-lasting materials.