The Leading FRP Product Manufacturer in Vietnam

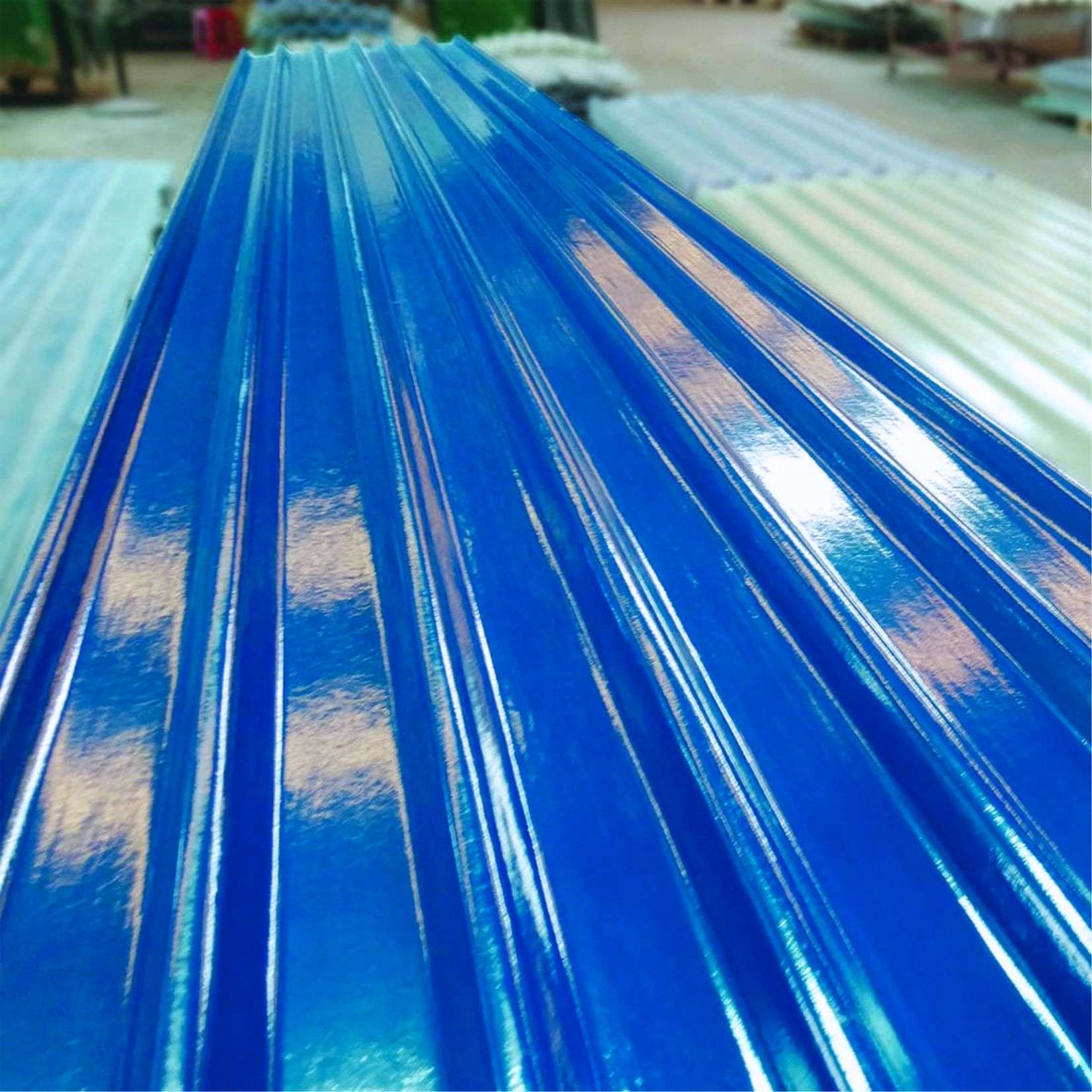

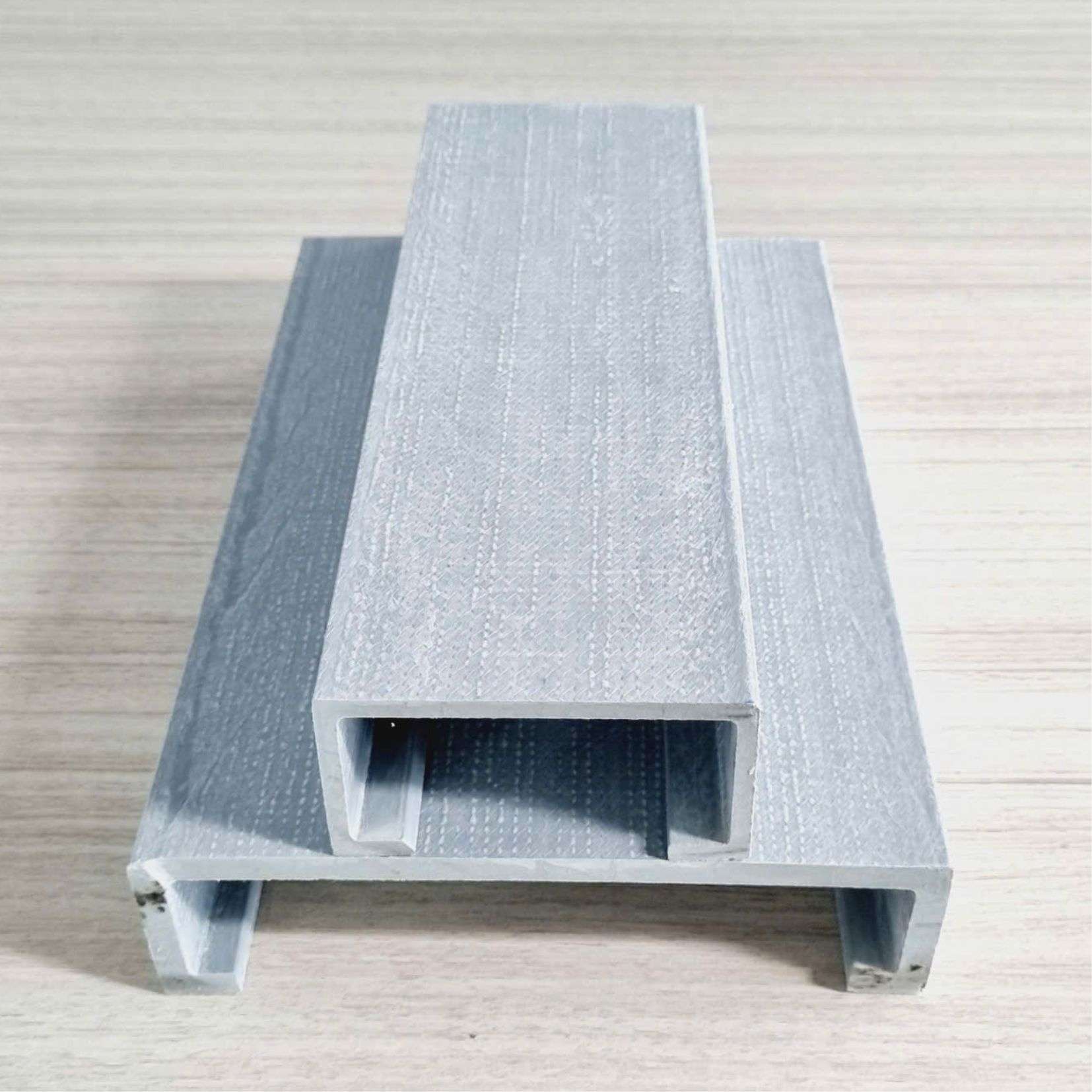

We offer high quality FRP panels, FRP grating, FRP pultrusion, FRP tank and other products made by OEM composite material with advanced technology and equipment from New Zealand and USA.

We export more than 100 containers of FRP products yearly to various markets: USA, Canada, Germany, Holland, Ireland, Japan, Korean, Middle East and other countries

We apply hand lay-up, Light RTM and Spray-up with USA equipment for OEM product made by composite, FRP materials.

With 28+ years of experience in FRP manufacturing, we always dedicate to deliver the best quality service. Your best FRP manufacturer from Vietnam.

About Us

The Front JSC is a leader in composite, FRP technology in Vietnam.

With more than 28 years of experience, we are confident to offer the best FRP, GRP (Fiber-reinforced glass) products. Besides our main products, composite roofing (FRP panels, translucent roofing, FRP anti-corrosion panels…), our other OEM products made by composite material such as FRP bins, FRP tanks,… have been delivered to customers from all over the world: USA, Canada, Germany, Holland, Ireland, Japan, Korean, Middle East and other countries

Our FRP/GRP products have been applied in various fields, including; agriculture, transportation, energy, public constructions, fertilizer and chenical factories…

We have a wholehearted commitment to be your trusted FRP partners.

With a long history in FRP , advanced technology, dedicated people, we thrive to provide the best composite FRP products with most reasonable price, satisfying all customer needs.

Sectors - Markets

We have completed orders from clients in various sectors.

Our composite products are dedicated, well-designed and very durable. They can sustain in harsh environment and last very long. Therefore, the application range is only limited by our imagination.

Step 1: Consultations

Consultations

Step 2: Modeling 3D

Modeling 3D

Step 3: Contract Sign

Contract Sign

Finish: Product Delivery

Product Delivery

Why Choose Us?

Our Vision is Our Mission

Our Markets