In a world where durability and sustainability are paramount, The Front brings cutting-edge FRP roofing technology from New Zealand to redefine building standards across industries.

Introduction to FRP Roofing by New Zealand Technology

FRP (Fiberglass Reinforced Plastic) roofing sheets are a type of composite material made from high-grade polyester resin combined with premium fiberglass. Unlike traditional metal roofing, FRP roofing is corrosion-resistant, UV-resistant, and withstands harsh chemical environments, making it a preferred choice for projects requiring high durability.

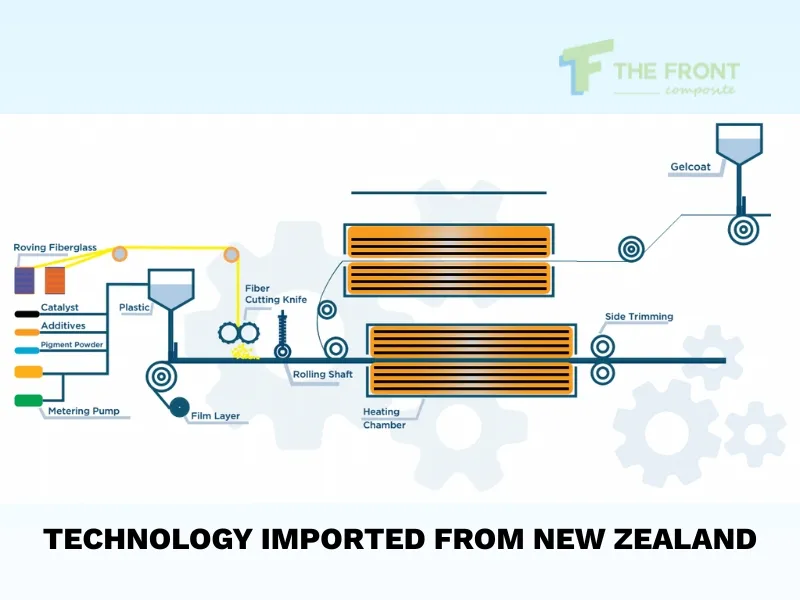

Production technology plays a key role in determining the quality of FRP roofing sheets. A standardized process ensures tight adhesion between layers, long-lasting durability, and uniform thickness and surface quality.

At The Front, we proudly adopt advanced manufacturing technology imported from New Zealand to produce FRP roofing that meets international standards.

FRP Roofing Manufacturing Technology Imported from New Zealand

The Front utilizes composite manufacturing technology imported from New Zealand—renowned worldwide for its innovation in composite production. The fully automated digital production line and specialized curing systems enhance the performance of each mixed material component, resulting in outstanding product quality.

Key highlights include:

- ISO 9001 certified process: Strict control over raw materials, temperature, and compression to ensure uniform thickness and bubble-free sheets.

- PET Heat Sealable Coating: Protects surface shine and boosts durability up to 20 years.

FRP Roofing Manufacturing Process

Step 1: Raw material preparation – Polyester resin, premium fiberglass, pigments, and additives.

Step 2: Material blending – Advanced blending technology from New Zealand ensures even distribution.

Step 3: Continuous extrusion – Automatic system pushes material through molds to form sheets with consistent thickness and bubble-free structure.

Step 4: PET and Gelcoat coating – Surface protection layer resists UV rays and corrosion, enhancing durability.

Step 5: Quality inspection – Rigorous checks for thickness, surface finish, clarity, and strength.

Step 6: Cutting, packaging, and distribution.

Key Advantages of New Zealand Technology

- Continuous extrusion technology produces sheets with uniform structure, smooth surfaces, and no air bubbles—enhancing durability and long-term quality consistency.

- Automated quality control system operates continuously during production, detecting and eliminating all technical defects to ensure every sheet meets the highest standards.

- UV-resistant PET coating acts as a “shield” against intense sunlight, maintaining color and flexibility for over 25 years without fading or cracking.

- Advanced fiberglass dispersion technology ensures even fiber distribution and deep penetration into the resin matrix—resulting in superior mechanical strength and heat resistance, ideal for industrial environments.

Real-World Applications of FRP Roofing Made with New Zealand Technology

FRP roofing produced with modern New Zealand technology is increasingly popular across various sectors thanks to its superior durability, chemical resistance, and aesthetic appeal.

- In industry: Ideal for chemical plants, factories, and warehouses—where corrosion resistance and harsh environmental tolerance are essential.

- In residential use: Perfect for house canopies, carports, and pool covers—offering both visual appeal and long-term UV resistance.

- In agriculture: Performs well in livestock farms, greenhouses, and composting zones—where high humidity and acidic conditions are common.

Conclusion – Why New Zealand Technology Is the Top Choice

Technology is the “heart” of high-performance FRP roofing. By pioneering the application of advanced production lines from New Zealand, The Front not only enhances the durability and corrosion resistance of each sheet but also provides customers with an efficient and cost-effective solution.

Choose advanced technology to build long-lasting structures.

The Front – Your trusted partner in creating a sustainable future with materials that stand the test of time.

THE FRONT JSC

Address: Block H19, St. N1, Nam Thuan Industrial Park, Duc Hoa Dong Ward, Duc Hoa District, Long An Province

Hotline: +(84)96-888-7363

Email: [email protected]