In environments where moisture, chemicals, extreme temperatures, or heavy traffic are a daily reality, traditional doors made of wood, metal, or aluminum often fail to meet long-term demands. Cracking, warping, corrosion, and costly maintenance are common issues with conventional door materials, especially in challenging climates like those found across Vietnam.

Enter the FRP door – a modern, durable, and practical solution engineered to perform under the toughest conditions. If you’re considering an upgrade for your facility, industrial site, or coastal property in Vietnam, this article will show you why choosing an FRP door is the smartest move you can make for long-term value and reliability.

What Is an FRP Door?

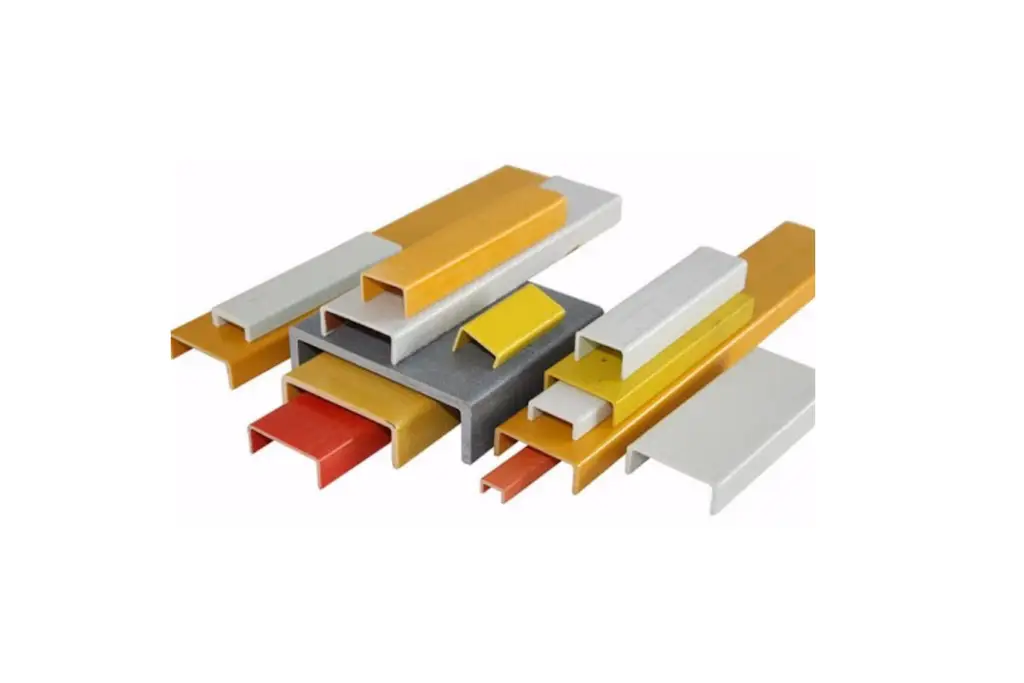

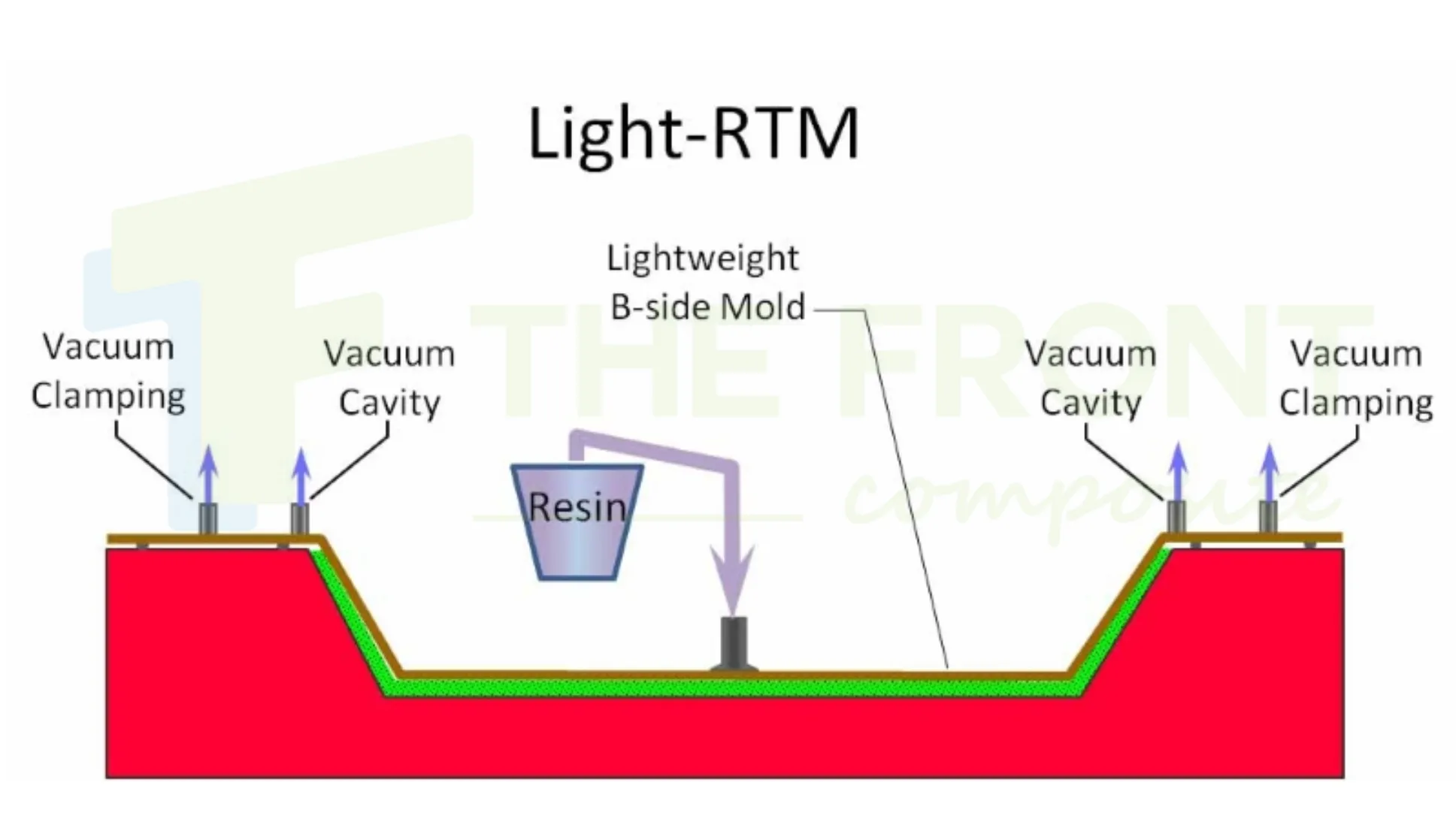

An FRP door (Fiberglass Reinforced Plastic door) is made from a composite material consisting of fiberglass fibers embedded within a tough polymer resin matrix. This construction delivers outstanding mechanical strength, lightweight performance, and superior resistance to a wide range of environmental threats.

Unlike traditional wood or metal doors, FRP doors are manufactured in a single, durable unit that is highly resistant to impacts, chemicals, moisture, and weathering, making them ideal for demanding applications.

Top Reasons Why FRP Doors Excel in Harsh Environments

1. Unmatched Resistance to Moisture and Humidity

One of the most significant advantages of an FRP door is its complete resistance to water. In humid, wet, or coastal environments, wood doors swell, crack, and rot, while metal doors corrode and weaken over time.

FRP doors, on the other hand, are non-porous and impermeable to moisture, meaning they:

- Do not warp, swell, or rot

- Maintain structural integrity even after prolonged exposure

- Require minimal maintenance to retain their appearance and function

Best suited for:

- Marine facilities

- Coastal properties

- Swimming pool areas

- Water treatment plants

2. Superior Chemical and Corrosion Resistance

Environments like chemical plants, laboratories, and food processing facilities expose doors to aggressive cleaning agents, chemical spills, and corrosive substances.

An FRP door is designed specifically to handle such exposure:

- Resistant to acids, alkalis, solvents, and cleaning chemicals

- Will not corrode, pit, or deteriorate over time

- Ensures a clean, safe, and compliant environment

Best suited for:

- Pharmaceutical manufacturing

- Industrial plants

- Chemical processing facilities

- Food and beverage production

3. High Impact and Heavy-Duty Performance

In busy commercial and industrial settings, doors are subjected to frequent impacts from carts, forklifts, gurneys, and other heavy equipment.

An FRP door offers:

- High strength-to-weight ratio

- Exceptional resistance to dents, scratches, and punctures

- Long-lasting performance even under heavy daily use

Their ability to withstand mechanical abuse makes FRP doors ideal for places where durability is non-negotiable.

Best suited for:

- Hospitals and healthcare centers

- Warehouses and logistics centers

- Educational institutions

- Airports and transportation hubs

4. Low Maintenance and Long Service Life

Wood doors require repainting. Metal doors need rust treatments. Aluminum frames often require frequent adjustments.

With an FRP door, maintenance needs are dramatically reduced:

- No painting, sealing, or refinishing required

- Easy cleaning with mild detergents

- Resistant to surface damage and discoloration

An FRP door can easily outlast traditional doors, often providing 20 to 30+ years of service even in demanding environments, saving both maintenance time and budget over its lifespan.

5. Fire Resistance and Safety Compliance

Modern FRP doors can be manufactured to meet stringent fire-resistance standards. Fire-rated FRP doors incorporate fire-retardant cores and specialized resins to maintain safety in case of emergencies.

Benefits include:

- UL fire ratings of up to 90 minutes

- Smoke control options

- ADA-compliant thresholds and accessible designs

Best suited for:

- Hospitals

- Commercial kitchens

- Industrial manufacturing plants

- High-occupancy facilities

6. Energy Efficiency and Insulation

FRP doors can be manufactured with insulated cores, greatly improving their thermal efficiency compared to metal or wood doors. This helps in:

- Reducing heating and cooling costs

- Maintaining temperature control in sensitive environments

- Supporting sustainable building certifications

Energy-efficient FRP doors are especially important for facilities seeking to lower operational costs and improve environmental performance.

Common Applications for FRP Doors in Harsh Environments

Because of their durability and resilience, FRP doors are widely used across multiple sectors:

| Sector | Application |

|---|---|

| Healthcare | Clean rooms, operating rooms, laboratories |

| Industrial | Warehouses, chemical plants, factories |

| Commercial | Schools, stadiums, shopping malls |

| Food & Beverage | Processing plants, kitchens, cold storage |

| Transportation | Airports, train stations, ferry terminals |

| Marine | Shipyards, coastal hotels, marina buildings |

Things to Consider When Choosing an FRP Door

Before purchasing or specifying an FRP door, consider these important factors:

- Fire Rating Requirements: Ensure compliance with building codes.

- Chemical Exposure: Select resin systems designed for your specific environment.

- Traffic Level: Choose door thickness and reinforcement appropriate for expected impact levels.

- Insulation Needs: Select insulated cores if energy efficiency is a priority.

- Design Aesthetics: Many FRP doors are available with customizable colors, finishes, and even woodgrain appearances.

Partnering with an experienced FRP door supplier ensures the right door is selected for your exact needs.

If you’re operating in a harsh, high-demand environment, investing in an FRP door is one of the smartest choices you can make. With unbeatable resistance to moisture, chemicals, impact, and extreme temperatures – especially important for industries in Vietnam – FRP doors outperform traditional materials at every level.

They reduce maintenance, enhance safety, and deliver long-term value far beyond initial installation – making them the clear choice for modern facilities throughout Vietnam.

Ready to upgrade to durable, high-performance FRP doors? Contact The Front today to explore premium FRP solutions designed to perform under the toughest conditions.