When it comes to the durability and performance of commercial and industrial door systems, every component matters. While door frames and panels get most of the attention, the threshold plays an equally critical role in maintaining energy efficiency, accessibility, and resistance to wear — especially in demanding environments in Vietnam. One of the most advanced solutions in modern threshold design is the FRP threshold.

What Is an FRP Threshold?

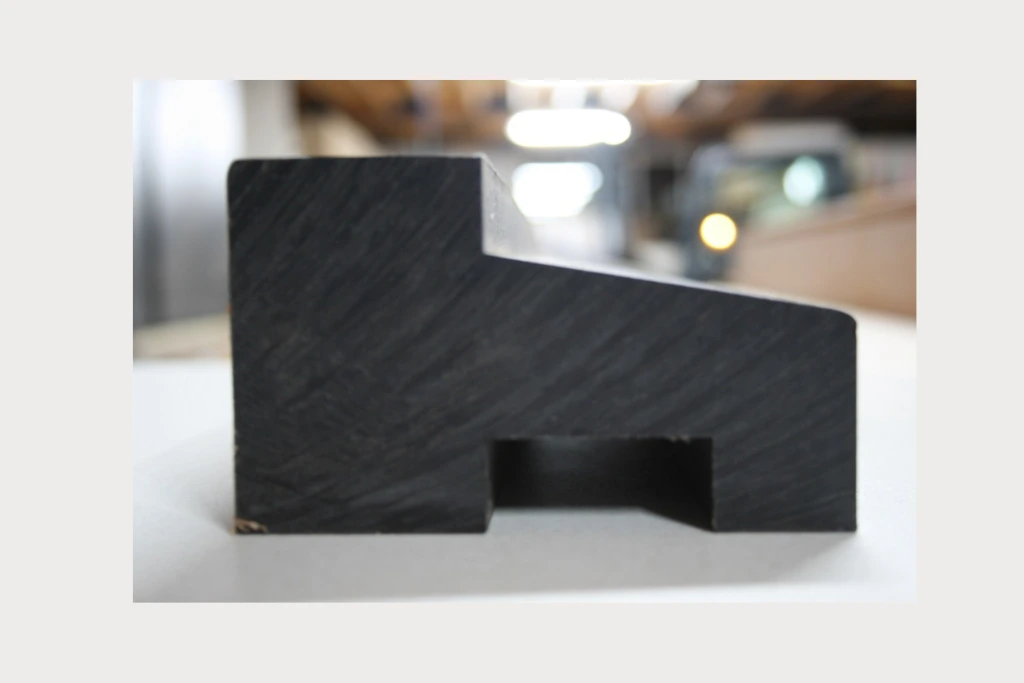

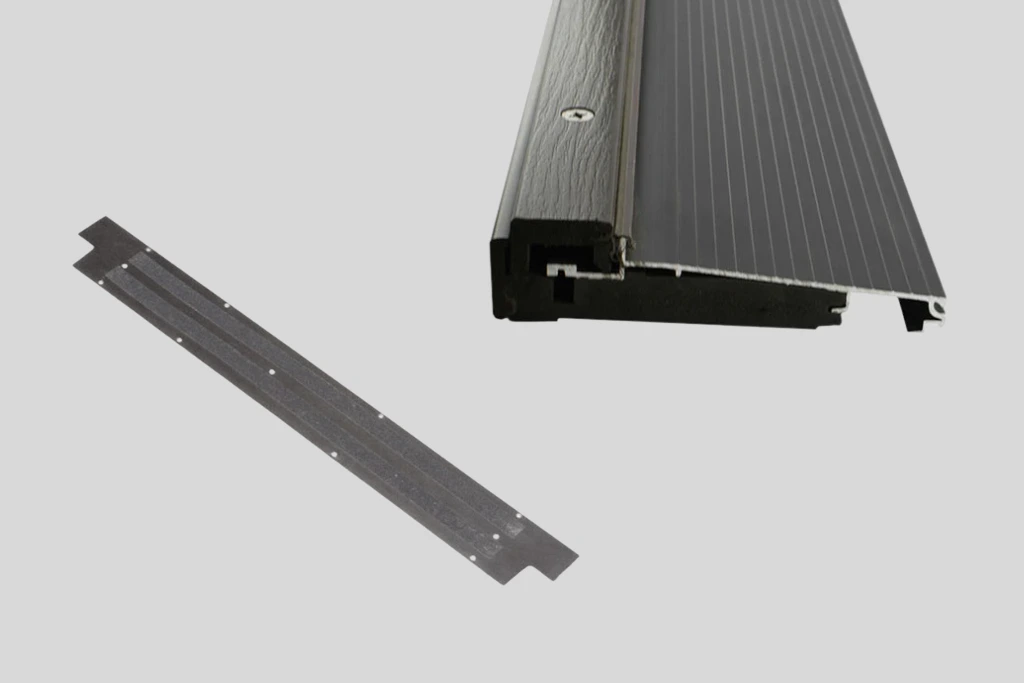

An FRP threshold is a structural doorway component made from fiberglass reinforced plastic—a composite material consisting of fiberglass strands embedded in a polymer resin. Designed to bridge the gap between a door and the floor, thresholds help seal out air, water, debris, and pests while ensuring smoother transitions between spaces.

What makes FRP thresholds unique is their combination of high strength, corrosion resistance, and low maintenance, making them suitable for both interior and exterior applications in high-traffic or harsh environments.

Key Features of FRP Thresholds

Superior Corrosion Resistance

Unlike metal thresholds that corrode over time—especially in areas exposed to moisture, chemicals, or salt air—FRP thresholds are non-reactive. They’re ideal for marine facilities, food processing plants, labs, and exterior doors in humid or coastal areas.

High Impact Strength

FRP thresholds are strong enough to withstand heavy foot traffic, rolling equipment, and impacts from carts or trolleys without cracking, denting, or warping.

Lightweight Yet Durable

Despite their toughness, FRP thresholds are relatively light, which makes them easy to handle and install. This also reduces structural load on the doorway.

Low Maintenance Requirements

They require no painting or sealing and can be cleaned easily with soap and water, which is particularly beneficial in hygiene-sensitive facilities.

Thermal and Electrical Insulation

FRP thresholds do not conduct heat or electricity, making them suitable for facilities where thermal or electrical conductivity is a concern.

ADA Accessibility

Many FRP thresholds are designed to meet ADA (Americans with Disabilities Act) requirements, featuring low-profile designs that allow easy wheelchair access while maintaining a seal.

Where Are FRP Thresholds Commonly Used?

FRP thresholds are widely used in a variety of industries and settings, including:

In these environments, exposure to moisture, chemicals, temperature changes, and constant use can wear down standard thresholds. FRP’s resilience makes it an ideal long-term solution.

- Healthcare facilities (hospitals, clinics)

- Food and beverage processing plants

- Marine and coastal buildings

- Pharmaceutical manufacturing

- Educational institutions

- Industrial plants and warehouses

- Cold storage facilities

FRP Threshold vs. Traditional Materials

When compared to other threshold materials like aluminum, stainless steel, or wood, FRP thresholds stand out in several ways. For corrosion resistance, FRP clearly outperforms both aluminum and wood, which are more prone to rust and rot respectively. Stainless steel offers decent resistance but comes at a higher cost.

In terms of maintenance, FRP requires virtually no upkeep, while wood needs frequent sealing or painting and aluminum may require periodic checks for oxidation. When it comes to impact resistance, FRP and stainless steel both perform well, while wood and aluminum can show wear more quickly.

FRP thresholds are also lightweight—similar to aluminum—but unlike metal, they offer excellent thermal and electrical insulation, making them safer and more energy-efficient. Over the product’s lifespan, FRP proves to be cost-effective due to its durability and minimal maintenance needs, especially when compared to high-maintenance wood or high-cost stainless steel.

Installation Considerations for FRP Thresholds

Installing an FRP threshold is relatively straightforward, but some considerations help ensure optimal performance:

- Substrate Preparation: Ensure the floor is level and clean before installation.

- Sealant Use: Apply waterproof, flexible sealant to prevent air and water infiltration.

- Anchoring: Use corrosion-resistant anchors for secure attachment, especially in wet or chemical-heavy environments.

- Transition Planning: Make sure the threshold integrates well with flooring materials and any adjacent ramps or mats to maintain ADA compliance.

Maintenance and Longevity

FRP thresholds are virtually maintenance-free, but periodic checks can extend their life even further:

- Clean periodically with mild soap and water to remove dirt and grime.

- Inspect seals to ensure they remain flexible and intact.

- Check for chips or damage from extreme impact (rare, but possible in heavy-duty zones).

With minimal care, an FRP threshold can easily last 20 years or more without needing replacement.

When to Consider Replacing Your Threshold with FRP

You should consider switching to an FRP threshold if:

- Your current metal threshold is rusting or corroded

- You need a hygienic, low-maintenance solution

- The facility is exposed to chemicals, saltwater, or extreme temperatures

- You’re updating doors for ADA compliance

- Long-term cost savings are a priority

FRP thresholds can be retrofitted to existing door systems in most cases, making them a simple but effective upgrade.

A door is only as strong as its weakest component — and in many cases, the threshold is that overlooked weak point. Upgrading to an FRP threshold is a smart move for any building owner or facility manager in Vietnam looking for a durable, corrosion-resistant, and low-maintenance solution.

From harsh industrial environments to hygiene-critical spaces like hospitals and food plants in Vietnam, FRP thresholds offer superior performance that saves time and money over the long term.

Ready to upgrade your door system with an FRP threshold? Contact The Front today to explore high-performance threshold options designed for every application in Vietnam.