Product Description

The Key Benefits of Eliclad® GC – Corrossion resitant FRP gelcoated panel

In industrial areas with highly corrosive environments or areas with saline contamination, the coating on the roofing sheet and the metal wall substrate may not perform as expected. To solve this problem, The Front has produced opaque roofing and walling sheets with FRP (fiberglass reinforced plastic) material to create a corrosion-resistant walling system to replace traditional materials.

Characteristics & Benefits only

Premium Gelcoat WON-SET 318

Incorporating Premium Gelcoat WON-SET 318 in the Eliclad® GC – Corrossion resitant FRP gelcoated panel nhances their UV resistance and weather durability. This high-quality gelcoat not only provides superior sheet clarity but also allows for the application of solid color pigmentation, ensuring a polished and aesthetically pleasing finish.

Surface Coatings

The Premium Gelcoat WON-SET 318 Gelcoat weather surface used in the Eliclad® GC offers superior sheet clarity and unsurpassed long-term resistance against UV degradation.

Advanced FRP Technology

Eliclad® GC leverages advanced FRP (Fiberglass Reinforced Plastic) technology to ensure superior corrosion resistance and durability. This technology is particularly effective in highly corrosive industrial sites and areas with high salt contamination, providing a reliable alternative to traditional materials like aluminum and steel.

Dual-Side Pigmentation

Eliclad® GC features advanced Alsynite Gelcoat manufacturing processes, which enable different solid color pigmentation on each side of the sheet. This technology is particularly beneficial when the underside of the sheet is exposed and not covered by a membrane, maintaining a uniform and appealing appearance.

Mildew and Fire Resistance

The panels are designed to inhibit mildew growth effectively and are constructed from fire-resistant thermosetting resin. This dual protection ensures that the panels remain hygienic and safe, even in challenging environmental conditions.

Customizable and Lightweight Design

Eliclad® GC are customizable to any length and available in various roof profiles, including flat sheets. Their lightweight design facilitates easy handling and installation while also reducing solar heat transmission and lowering freight costs, making them a versatile and cost-effective choice for diverse applications.

Operating Temperature

Eliclad® GC will not become brittle with age and will not soften or crack within the designed temperature operating range of -10°C to +90°C.

Chemical Resistance

Eliclad® GC has no known chemical reaction with any construction materials;

The sheeting is resistant to solar deterioration and most corrosive atmospheres;

It is unaffected by solvents, including hydrocarbons, and provides excellent resistance to most corrosive acids and alkalis.

Thermal Expansion

2.2 x 10.5 cm / cm °C E.g. 7m long sheet with a 40°C temperature change = 2.2 x 10.5 x (10 x 100) x 7 x 40 = 6.16mm per 7m length at 40°C temperature rise.

Safety

According to construction standard requirements, lighted roofing products are classified as “Crusty Roofing” and are unsuitable for moving on roofing surfaces (except for Eliclad GC Ultra-Safe Corrosion resitant FRP gelcoated panels & load bearing panel). It is recommended to install a safety net under the location of installing lighted roofing panels or walkways with Grating Ultralite of The Front®.

Moisture

If the Eliclad® GC is installed in a constantly damp area, please get in touch with our technical department before ordering.

Product Handling

Care must be taken when handling and installing the product to avoid stress damage and scratching of the surface.

Warranty

Eliclad® GC are warranted for 25 years of durability and 15 years of light transmission.

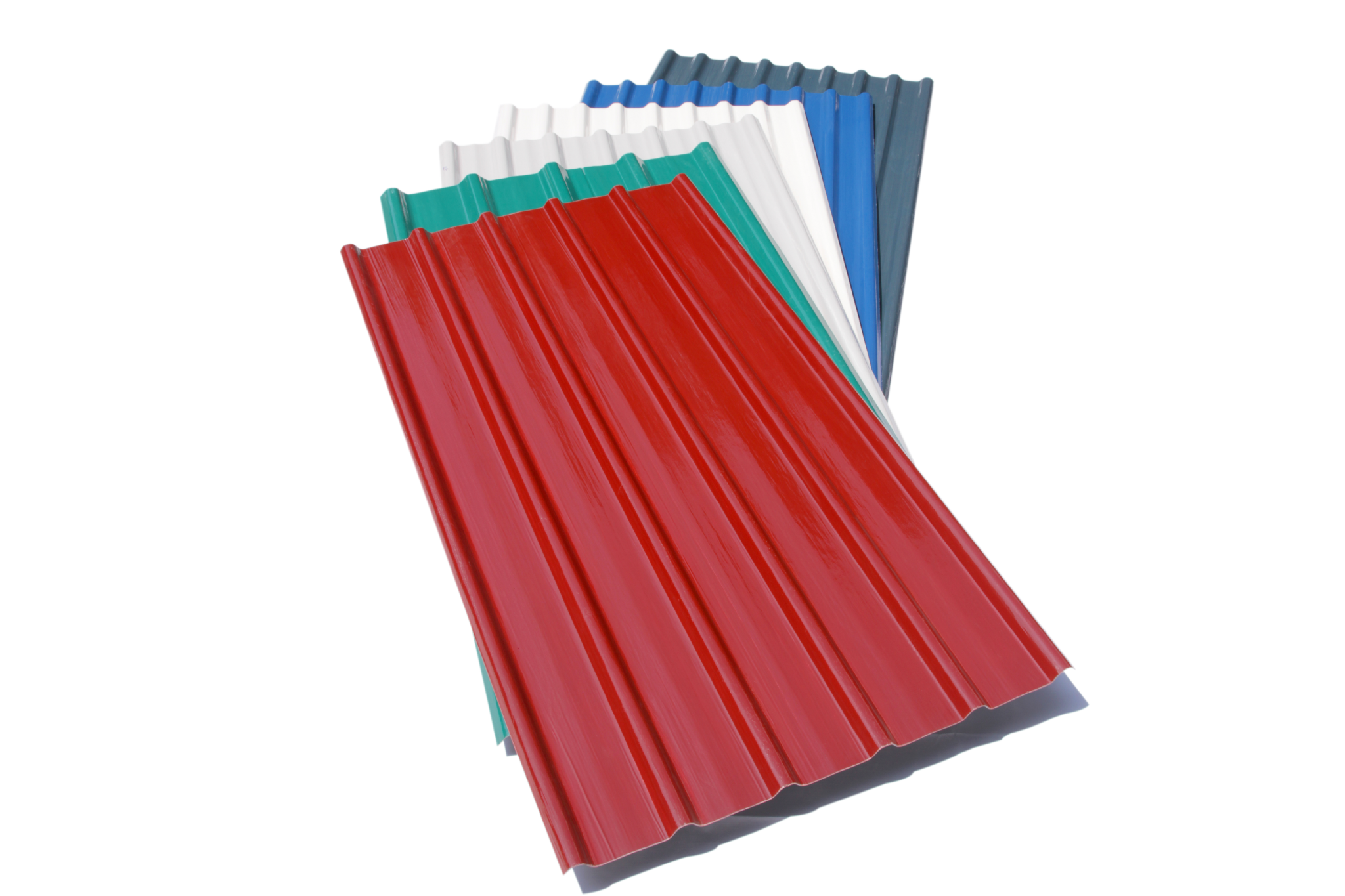

Color

Eliclad® GC – Corrossion resitant FRP gelcoated panel provides an excellent opportunity to replicate the colours usually associated with pre-painted metal roofing and cladding products. The standard color range is Yellow, Grey, and Blue. Other colors to suit specific design criteria are available on request. All Eliclad® GC are subject to minimum order quantities.

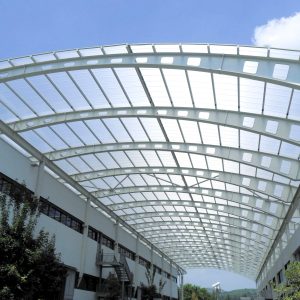

Applications of Eliclad® GC – Corrossion resitant FRP gelcoated panel

Industrial Applications

Eliclad® GC – Corrossion resitant FRP gelcoated panel are ideal for industrial environments requiring high corrosion resistance. These panels provide long-lasting protection against harsh chemicals in acid plants and smelters. In galvanizing plants, they offer durability and withstand the rigorous processes involved.

Agricultural Applications

Eliclad® GC is perfect for poultry and animal sheds in agricultural settings. Their mildew-resistant properties ensure clean and safe environments for livestock. For instance, these panels help maintain hygiene and reduce maintenance costs in large poultry farms.

Marine and Coastal Applications

Eliclad® GC are highly effective in extreme marine environments. For coastal buildings, such as those in fishing ports or marinas, these panels resist salt and humidity, offering protection against the corrosive effects of sea air and harsh weather.

Specialized Facility Applications

Eliclad® GC excels in specialized facilities like wool scouring plants and fertilizer buildings. In wool scouring plants, the panels provide excellent performance against wet and chemical-rich processes. In geothermal areas, these panels withstand extreme temperatures and corrosive elements, ensuring the longevity and safety of the structures.

Where corrosion may concern the underside of the roofing and cladding system, the Front® Proprietary high-polished corrosion-resistant surface can be applied to the bottom of the sheet. Vinyl Ester Resin can be incorporated for maximum protection.

THE FRONT JSC

Address: Block H19, St. N1, Nam Thuan Industrial Park, Duc Hoa Dong Ward, Duc Hoa District, Long An Province

Hotline: +(84)96-888-7363

Email: [email protected]

Đánh giá

Chưa có đánh giá nào.