In the realm of modern manufacturing and infrastructure development, component optimization plays a critical role in achieving structural efficiency, durability, and performance. Pultruded fiberglass channels have emerged as a key material solution for OEMs (Original Equipment Manufacturers) and engineers designing machinery frameworks, structural supports, and cable systems. This article explores the technical characteristics, performance benefits, and diverse applications of pultruded fiberglass channels in machinery and infrastructure projects.

What Are Pultruded Fiberglass Channels?

Pultruded fiberglass channels are structural profiles created using the pultrusion process, a continuous manufacturing method in which glass fibers are pulled through a thermosetting resin and shaped into a solid cross-section through a heated die. The result is a lightweight yet extremely strong component with high dimensional stability, corrosion resistance, and mechanical integrity.

Material Composition and Structural Properties of Pultruded Fiberglass Channels

Pultruded fiberglass channels typically consist of:

- Glass fiber reinforcements: Provide tensile strength and stiffness

- Resin matrix (polyester, vinyl ester, or epoxy): Offers chemical resistance and environmental durability

- Surface veil: Enhances UV resistance and protects fibers from damage

These components combine to deliver superior mechanical properties including:

- High tensile and flexural strength

- Excellent stiffness-to-weight ratio

- Dimensional stability across temperature changes

- Resistance to corrosion, moisture, and chemicals

Performance Advantages of Pultruded Fiberglass Channels in OEM and Infrastructure Applications

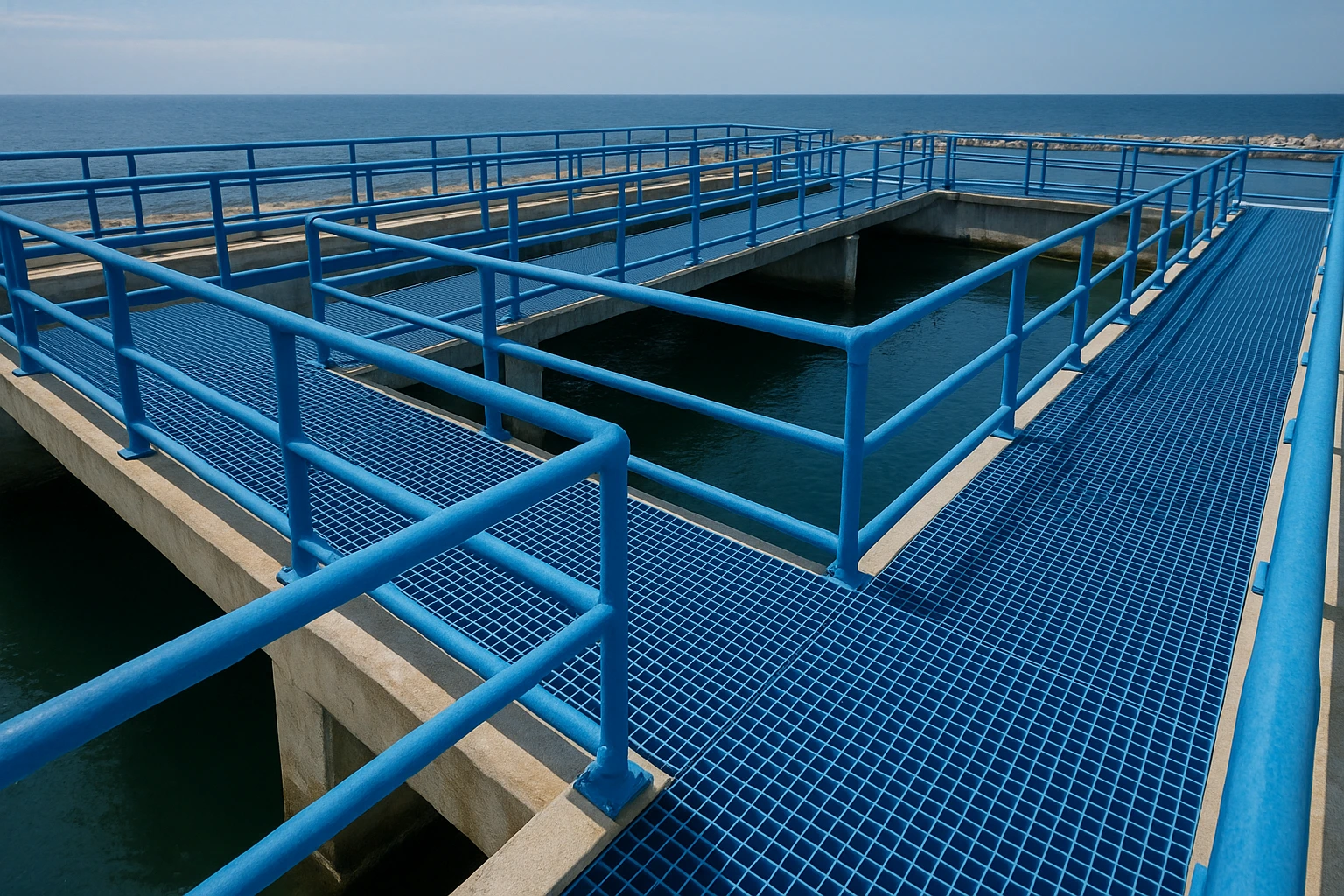

- Corrosion Resistance In industrial settings where metal components are susceptible to rust, pultruded fiberglass channels offer long-term performance without the need for protective coatings or maintenance. They are ideal for marine environments, wastewater plants, and chemical processing facilities.

- Lightweight and High Strength These channels are significantly lighter than steel or aluminum, reducing structural load and making them easier to transport and install. Despite their weight, they maintain comparable strength, making them suitable for structural frames and equipment housings.

- Electrical and Thermal Insulation Fiberglass is inherently non-conductive, providing built-in electrical insulation. This makes pultruded fiberglass channels an excellent choice for cable trays, control panels, and components near live electrical systems.

- Dimensional Precision and Repeatability The pultrusion process ensures consistent cross-sectional dimensions, which is critical for OEMs requiring uniformity across large production volumes.

- Fire Retardant Capabilities With specialized resin systems, pultruded fiberglass channels can be formulated to meet fire safety standards, allowing their use in enclosed or high-risk environments.

Key Applications of Pultruded Fiberglass Channels in Machinery and Infrastructure

- Equipment Frames and Machine Bases: Used in assembly lines, conveyor supports, and robotic platforms where non-corrosive and lightweight structures are needed.

- Cable Support Systems: Serve as trays, guides, or protective enclosures for cables in electrical or data systems.

- Structural Bracing and Racking: Provide stability in warehouse storage, panel mounting, or modular enclosures.

- Walkways, Platforms, and Access Systems: Integrated into catwalks and stairs in industrial or offshore facilities due to their slip resistance and durability.

- Utility and Rail Infrastructure: Used in signal housing, drainage support, and electrical containment systems near railways or roadways.

Design and Fabrication Considerations for Pultruded Fiberglass Channels

- Machinability: Pultruded fiberglass channels can be drilled, cut, and machined with carbide-tipped tools.

- Joining Techniques: Assembly can be done using mechanical fasteners, adhesives, or molded connections depending on load and exposure requirements.

- Environmental Exposure: Selection of appropriate resin systems ensures long-term performance in UV, salt spray, chemical, or high-temperature conditions.

- Customization Options: Channels are available in various shapes (U-channel, C-channel, I-beam profiles) and can be fabricated to custom lengths, wall thicknesses, and colors.

Economic and Sustainability Benefits of Pultruded Fiberglass Channels

- Reduced Lifecycle Costs: Minimal maintenance, no painting or corrosion control, and long service life translate to lower operational expenses.

- Installation Efficiency: Lightweight material reduces installation labor and eliminates heavy lifting equipment.

- Sustainable Materials: Some pultruded fiberglass products use recyclable resins or bio-based materials, contributing to sustainability goals.

Pultruded fiberglass channels are redefining what engineers and OEMs can achieve in demanding machinery and infrastructure applications. With a unique combination of strength, corrosion resistance, and design flexibility, these components offer optimized solutions that outperform conventional materials in cost, performance, and sustainability. As global industries move toward lightweight and maintenance-free structures, pultruded fiberglass channels stand out as a high-performance material for the future.

Partner with The Front Industrial At The Front Industrial, we manufacture precision-engineered pultruded fiberglass channels tailored to industrial and OEM applications. Contact us to learn how our advanced composites can elevate your next machinery or infrastructure project.